WARNING

- Electrical power must be supplied

through an external circuit breaker or fuse protection.

An external switch must be provided to turn off

power. Always turn off power before removing the

internal field wiring panel.

Pneumatic connections:

Connect air supply and output lines to the 1/8” NPT

connections at the bottom of the controller The center

connection is for air exhaust and is supplied with a porous

metal filter/silencer which should not be removed.

Corrosion resistant 3/8 in. O.D. tubing or 1/4 in. pipe is

recommended for the air lines. Connect air supply to the

right hand connection labeled “Input” and output to left

hand connection labeled “Output” to actuator. See Figure 1.

The supply line should be fitted with a pressure gauge and 50

micron filter/regulator to remove any floating particles. If the

supply air is mixed with traces of oil, a filter capable of

removing oil should be used. (CAUTION: Some lubricating

oils permanently damage solenoid valves.)

W A R N I N G

- Turn off electrical power before

removing the internal field wiring panel

Field Wiring:

1.

After mounting the PMC-1 at the desired location, open

the cover by loosening 5 screws and the thumb screw.

Then remove the field wiring panel by loosening two

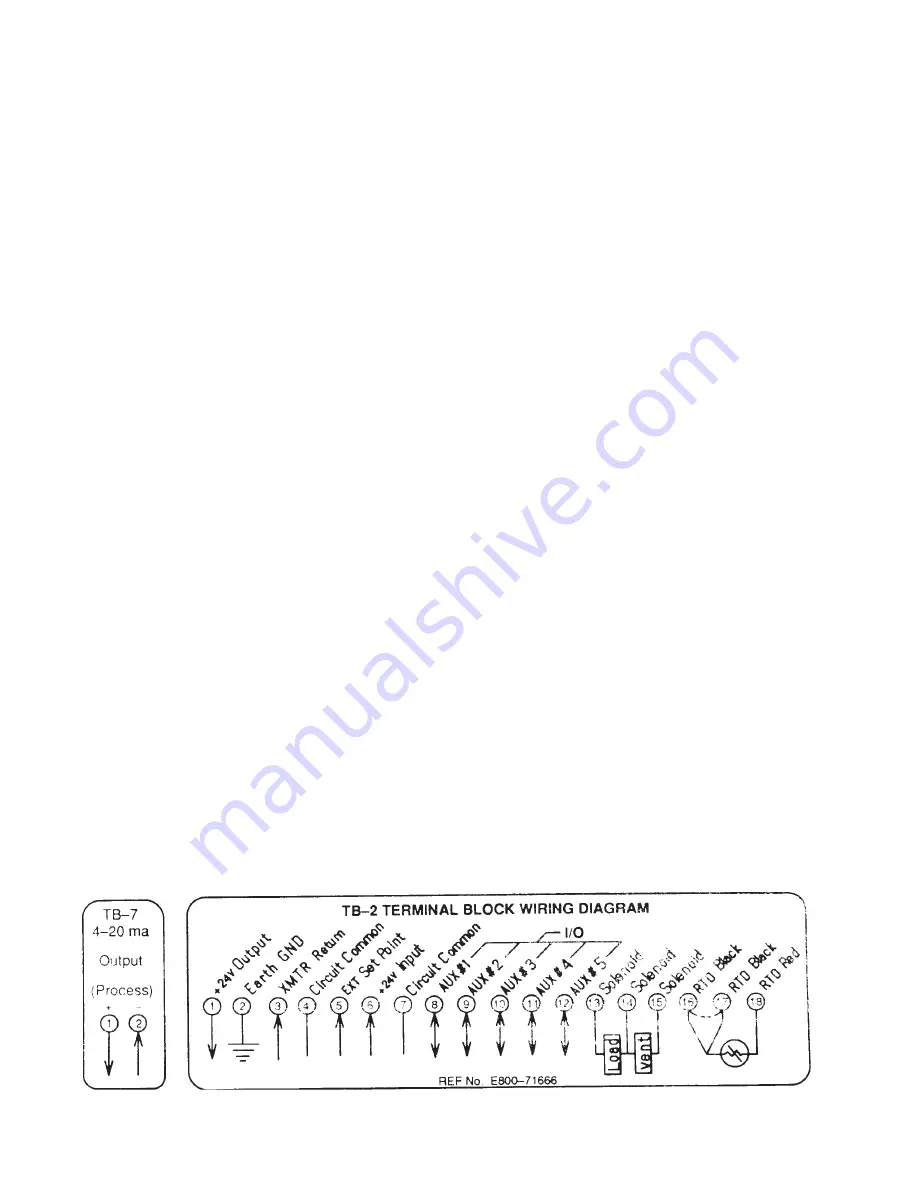

captive screws. The terminal block wiring diagram

shown in Figure 2 appears on the back of the panel.

Power and signal lines should be routed through

separate conduits to avoid interference. Transmitter or

RTD signal lines should use shielded cable grounded at

terminal 2 in insure against RF interference.

2.

Connect the transmitter wires as shown in Figure 3 . A

two wire transmitter should be powered with the 24v DC

supply from the PMC-1 by connecting the positive wire

to terminal number 1 and the other transmitter wire to

terminal 3 of TB-2. Twisted pair wires can be used for

connecting the transmitter to the PMC-1. If a shielded

pair of wires is used,connect the shield to terminal 2 of

TB-2. Jumper at J5/J6 must be on J5. For 4-wire

transmitters,see Appendix B.

3.

For external set point connection (4-20mA) connect two

wires to terminals 5 and 4 of TB-2. Terminal 5 is positive

(current flows into terminal 5) and terminal 4 is

negative. (See Figure 4)

A. Introduction

The Leslie PMC-1 electro-pneumatic controller can be used

to control pressure, temperature. liquid level, and other

process variables. It accepts signals from any standard 4-20

mA transmitter and provides a pneumatic output to operate a

diaphragm control valve, etc. It provides the following

features:

1)

The controller supplies 24 volt D C. power for the

transmitter, eliminating the need for a separate D.C.

power supply.

2)

It provides high volume air output at pressures up to 100

psig to directly operate a diaphragm control valve. I/P

transducers and valve positioners are not required or

recommended.

3)

There are no small air orifices to plug or foul (.060” dia.

solenoid ports)

4)

There is no air consumption except when air is being

loaded onto the control valve diaphragm.

B. Operation

The electronic circuit of the controller compares the signal

from the transmitter to the desired set point. If the error is

greater than the dead band, electrical pulses are sent to one

of the two internal air solenoid valves. One valve increases

output air pressure and the other bleeds it. Each time a pulse

is received, the resulting pressure on the diaphragm of the

control valve increases or decreases slightly. If the error is

large, the solenoid valves are held open longer to increase the

speed of output changes. For small errors, the pulse width is

decreased to prevent overshoot. The response speed

adjustment can be used to control how quickly the output

changes for a given error. Adjusting the dead band will allow

the controller to ignore small changes or “noise” in the

system. The overall result is a more accurate and stable

system.

C. Installation

Mount the controller in a location that will allow access to

the internal adjustments. See Figure 1 for mounting

dimensions. It should be mounted in a location where the

temperature will be between -4°F and 140°F. Temperatures

above or below these limits will affect the LCD although the

controller would continue to function. A location within 50

ft. of the control valve is recommended to reduce time lags in

the pneumatic signal. Where the distance to the control valve

is large, an optional external solenoid valve package (PMC-1

local control module model RCS-90) can be used.

FIGURE 2

4