Maintenance

Maintenance operations

Changing the oil

68

Lenze ¯ MA 12.0018 ¯ 4.1

7.3.4

Changing the oil

Stop!

¯ Secure the drive system and machinery against unintended movement

or mains power−up.

¯ The gearbox should be lukewarm in order that the oil flows well but

there is no risk of scalding.

¯ Only use lubricant types that match the nameplate or are listed in

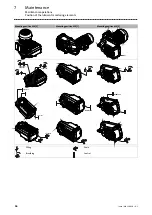

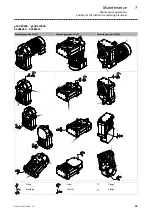

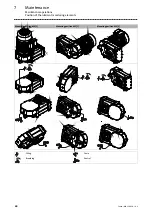

1. Place receptacle under oil drain plug.

2. Remove breathing / oil filler plug.

3. Completely drain lubricant by removing the oil drain plug.

4. Reinsert drain plug (if necessary, replace seal).

5. Fill in lubricant through filler hole (quantities see nameplate).

6. Screw in breathing / oil filler plug.

7. Dispose of waste oil according to the applicable regulations.

Note!

Change from the CLP or CLP HC standard gearbox oil to the

food−compatible CLP xx xxx USDA H1 gearbox oil.

The oil drainage holes do not allow for complete draining of the gearbox

in all cases. Then a residual amount of oil remains in the gearbox. If a

change−over to a food−compatible gearbox oil is to be effected, the

gearbox must be rinsed thoroughly with the food−compatible gearbox oil.

7.3.5

Lubricate roller bearings

The roller bearings on motors and gearboxes from Lenze are filled with the greases

listed below:

Ambient temperature

Manufacturer

Type

Gearbox roller bearing

−30 °C ... +50 °C

−30 °C ... +80 °C

−40 °C ... +60 °C

Fuchs

Klüber

Klüber

Renolit H 443

Petamo 133 N

Microlube GLY 92

Motor roller bearing

−30 °C ... +70 °C

−40 °C ... +80 °C

Lubcon

Klüber

Thermoplex 2TML

Asonic GHY 72

Special grease for gearbox roller bearings

Low−temperature oils,

observe critical starting

performance at low

temperatures

−40 °C ... +80 °C

Klüber

Asonic GHY 72

Biopetroleum (lubricant

for forestry, agriculture

and water supply and

distribution)

−40 °C ... +50 °C

Fuchs

Plantogel 0120S

Note!

Clean roller bearings before applying new grease!