Mechanical installation

Mounting of g500 short/servo adapters with clamping connection

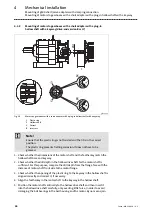

Attachment of gearboxes with hollow shafts and keyway

40

Lenze ¯ MA 12.0018 ¯ 4.1

Dismounting

Stop!

¯ Before dismantling the machine shaft, mount an adequately

dimensioned load handling device at the gearbox.

¯ Ensure pretensioning of the drive mechanism, preventing the gearbox

from falling into the drive mechanism when it is loosened from the

plug−in shaft.

¯ When removing the hollow shaft via the housing, impermissibly great

forces may be generated.

¯ Tensioning of the hollow shaft causes a bearing failure and damage of

the gearbox housing.

1. Undo axial gearbox locking in the hollow shaft.

2. Remove/extract the gearbox from the motor shaft using an appropriate auxiliary

tool (LEERER MERKER).

Fig. 12

Disassembly of gearboxes with hollow shaft, with auxiliary tool

Auxiliary tool (recommended dimensions)

Æ

d

H7

b

±

0.1

c

8

c

9

c

10

d

1

±

0.1

d

2

d

3

t −0.1

t

1

25

7.8

10

3

−−−

24.8

M10

−−−

28

5.5

30

7.8

10

3

−−−

29.8

M10

−−−

33

5.5

35

9.8

12

3

−−−

34.8

M12

−−−

38

6

40

11.8

12

4

−−−

39.8

M16

−−−

43

6

45

13.8

12

4

−−−

44.8

M16

−−−

48.5

7

50

13.8

12

5

−−−

49.8

M16

−−−

53.5

7

55

15.8

16

5

−−−

54.8

M20

−−−

59

7.5

60

17.8

16

5

−−−

59.8

M20

−−−

64.1

8

70

19.8

16

5

−−−

69.8

M20

−−−

74.1

8

80

21.8

20

5

−−−

79.8

M20

−−−

85.1

9

90

24.8

10

10

−−−

89.8

M20

72

95

11

100

27.8

15

10

−−−

99.8

M24

80

106

12

120

31.8

15

10

−−−

119.8

M24

80

127

15

Tab. 4

Dimensions in mm