Mechanical installation

Mounting of g500 short/servo adapters with clamping connection

Coupling hubs

34

Lenze ¯ MA 12.0018 ¯ 4.1

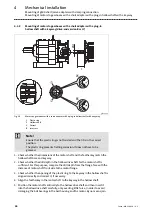

Mounting the clamping ring hub

1

2

3

Fig. 9

Coupling

1

Clamping ring hub

2

Clamping ring

3

Clamping screws (DIN912)

Note!

The motor shaft must be designed with fit k6.

1. Slightly oil contact surfaces of the motor shaft using low−viscosity lubricating oil

such as Castrol 4 in 1" or Klüber Quietsch Ex".

Stop!

Do not use oils and greases with molybdenum disulphide or extreme

pressure additives such as lubricating grease pastes!

2. Slightly loosen clamping screws in the coupling hub.

–

Fit coupling hub on the motor shaft using a center hole thread (do not mount by

hammer strokes, in order to avoid damage to the roller bearings in the motor).

–

Observe mounting dimension m of the coupling hub (see Tab. 2).

3. Align hub and slightly tighten clamping screws until they are fitting closely.

4. Tighten the clamping screws evenly crosswise in several steps until the indicated

tightening torque is reached (see Tab. 2).

5. Lay spider in the coupling claw on the gearbox side.

–

The mounting process can be facilitated by lightly greasing or oiling the ring

gear sides or the hub sides. For this purpose, only use mineral oil−based

lubricants without additives, silicone−based lubricants, or vaseline.

6. Align claws of the motor−side coupling hub with its counterpart.

7. Slowly push on motor, and bolt on to the gearbox flange.