Page 7

3.57kg) 9-

When the absolute pressure require

ment above has been met, disconnect the manifold

hose from the vacuum pump and connect it to an

upright bottle of R22 refrigerant. Open the manifold

gauge valves to break the vacuum in the line set and

indoor unit. Close manifold gauge valves and shut

off R22 bottle and remove manifold gauge set.

START-UP

IMPORTANT

HP25-413/463-1Y three-phase units only-Crank

case heater must be energized 24 hours before at

tempting to start compressor. Compressor dam

age may occur from slugging. To prevent com

pressor operation, set thermostat demand so

there is no demand. Apply power to unit.

Cooling Start-up

1- Rotate fan to check for frozen bearings or binding.

2- Inspect all factory and field-installed wiring for

loose connections.

3- Open liquid line and vapor line service valves to re

lease refrigerant charge (contained in heat pump

unit) into the system.

4- Replace stem caps and secure finger tight plus an

additional 1/6th turn.

5- Check voltage supply at the disconnect switch.

The voltage must be within the range listed on the

unit nameplate. If not, do not start the equipment

until the power company has been consulted and

the voltage condition corrected.

6- Set the thermostat for a cooling demand, turn on

power to the indoor blower coil and close heat

pump unit disconnect switch to start the unit.

7- Recheck unit voltage with unit running. Power

must be within range shown on unit nameplate.

Check amperage draw of unit. Refer to unit name

plate for correct running amps.

Three-Phase Compressor Rotation

Three-phase scroll compressors must be phased se

quentially to ensure correct compressor rotation and

operation. At compressor start-up, a rise in discharge

and drop in suction pressures indicate proper com

pressor phasing and operation. If discharge and suc

tions pressures do not perform normally, follow the

steps below to correctly phase in the unit.

1- Disconnect power to the unit.

2- Reverse any two field power leads to the unit.

3- Reapply power to the unit.

Discharge and suction pressures should operate at

their normal start-up ranges.

NOTE-Compressor noise level will be significantly

higher when phasing is incorrect and the unit will not

provide cooling when compressor is operating back

wards. Continued backward operation will cause the

compressor to cycle on internal protector.

CHARGING

It is desirable to charge the system in the cooling cycle

if weather conditions permit. However, if the unit must

be charged in the heating season, one of the following

procedures must be followed to ensure proper system

charge.

If the system is completely void of refrigerant, the rec

ommended and most accurate method of charging is

to weigh the refrigerant into the unit according to the

total amount shown on the unit nameplate and in table

3. Refer to the Lennox Unit Information Service manual

for proper procedure.

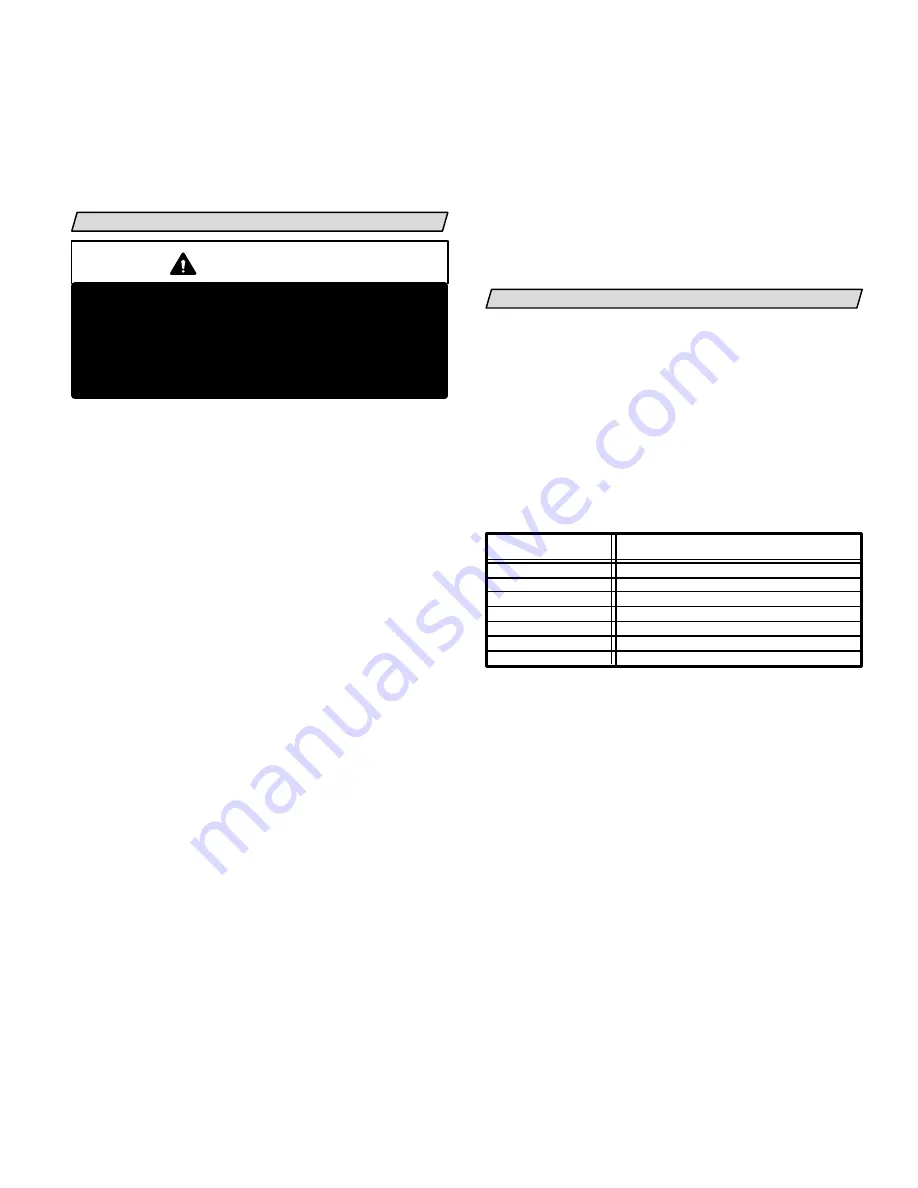

TABLE 3

Model

Refrigerant Charge R-22

HP25-211

HP25-311

HP25-410

HP25-460

7 lbs. 10 oz. (3.46 kg)

10 lbs. 4 oz. (4.65 kg)

11 lbs.4 oz. (5.10 kg)

12 lbs. 8 oz. (5.67 kg)

HP25-261

8 lbs. 14 oz. (4.03 kg)

HP25-510

18 lbs. 8 oz. (8.39 kg)

HP25-650

23 lbs. 14 oz. (10.83 kg)

If weighing facilities are not available or if unit is just

low on charge, use the following procedure:

1- Connect gauge manifold as shown in figure 7.

Connect an upright R-22 (HCFC-22) drum to center

port of gauge manifold.

2- Record outdoor ambient temperature.

3- Set room thermostat to 74

F (23

C) in Emergen

cy Heat" or Heat" position and allow unit to run

until heating demand is satisfied. This will create

the necessary load for proper charging of system

in cooling cycle. Change thermostat setting to

68

F (20

C) in Cool" position. Allow unit to run

until system pressures stabilize.

4- Check to make sure that thermometer well is filled

with mineral oil before checking liquid line tem

perature.