Page 9

Compressor Oil Charge

Table 6 gives compressor oil charge for HP25 units. Re

fer to Lennox Cooling Service Handbook for correct pro

cedure for checking and adding compressor oil.

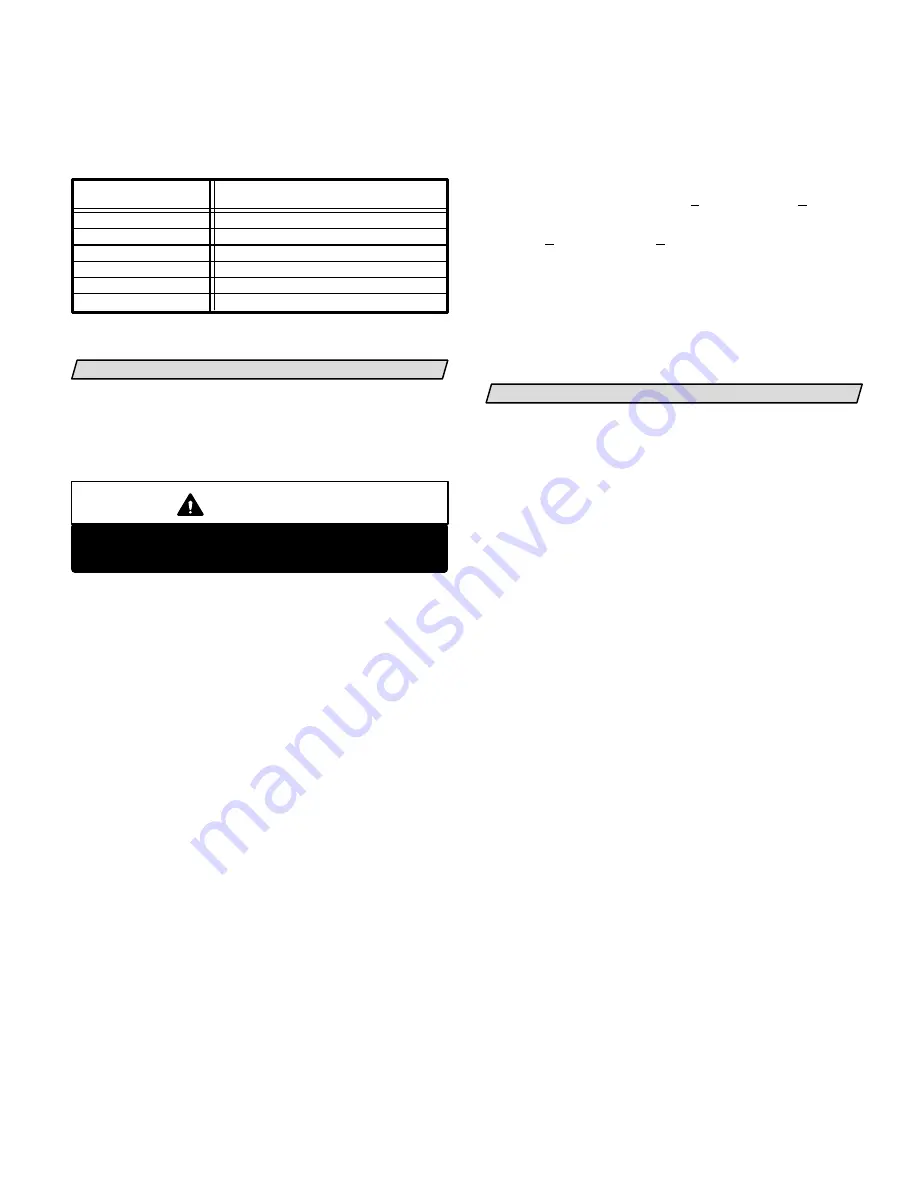

COMPRESSOR OIL CHARGE

TABLE 6

UNIT MODEL NO.

COMPRESSOR OIL CHARGE

ounces (liters)

HP25-211

HP25-410

HP25-460

38 oz.* (1.12 L)

*Shipped with conventional white oil (Sontex 200LT). 3GS oil may be

used if additional oil is required.

34 oz.* (1.01 L)

HP25-261 & -311

28 oz.* (0.83 L)

HP25-510

52 oz.* (1.54 L)

HP25-650

54 oz.* (1.60 L)

24 oz.* (0.71 L)

SYSTEM OPERATION

Discharge Thermostat

The scroll compressor is equipped with a discharge

thermostat which prevents the occurrence of danger

ously high discharge temperatures. This thermostat

cuts in at 130

F (54

C) and cuts out at 280

F (138

C) .

CAUTION

Danger of Equipment Damage.

Do not bypass the discharge thermostat.

Filter Drier

The drier is equipped with an internal check valve for

correct refrigerant flow (Refer to figure 7). If replace

ment is necessary, order another of like design and ca

pacity. A liquid line strainer gives additional compressor

protection.

Thermostat Operation

Some heat pump thermostats incorporate isolating

contacts and an emergency heat function (which in

cludes an amber indicating light). The thermostat is

not included with the unit and must be purchased

separately.

Emergency Heat (Amber Light)

An emergency heat function is designed into some ther

mostats. This feature is applicable only to those systems

with auxiliary electric heat staged by outdoor thermo

stats. When the thermostat is placed in the emergency

heat position, the outdoor unit control circuit is isolated

from power and field-provided relays by-pass the out

door thermostats. An amber indicating light simulta

neously comes on to remind the homeowner that the

unit is operating in the emergency heat mode.

Emergency heat is usually used during a heat pump

shutdown.

Compressor Timed-Off Control

This unit is equipped with a time delay which protects

the compressor by preventing short-cycling.

High Pressure Switch

The HP25 is equipped with an auto-reset high pressure

switch (single-pole, single-throw) which is located on

the liquid line. The switch shuts off the compressor

when discharge pressure rises above the factory set

ting. The switch is normally closed and is permanently

adjusted to trip (open) at 410 + 10 psig (2827 + 69 kPa).

The switch resets (closes) when the pressure drops be

low 210 + 20 psig ( 1448+138 kPa).

Crankcase Heater

HP25-413 & -463-1Y three-phase units only are

equipped with a crankcase heater which must be ener

gized for 24 hours before attempting to start compres

sor. To prevent compressor operation, set thermostat

so there is no demand. Apply power to unit.

DEFROST SYSTEM

The defrost system includes two components: a de

frost thermostat, and a defrost control.

Defrost Thermostat

The defrost thermostat is mounted on the liquid line be

tween the check/expansion valve and the distributor.

When defrost thermostat senses 35

F (2

C) or cooler, its

contacts close and send a signal to the defrost control

board to start the defrost timing. It also terminates de

frost when the liquid line warms up to 70

F (21

C).

Defrost Control

The defrost control board has the combined func

tions of a time/temperature defrost control, defrost

relay, time delay, diagnostic LEDs and field connec

tion terminal strip.

The control provides automatic switching from normal

heating operation to defrost mode and back. During

compressor cycle (call for defrost), the control accumu

lates compressor run times at 30, 60 or 90 minute field

adjustable intervals. If the defrost thermostat remains

closed when the accumulated compressor run time

ends, the defrost relay is energized and defrost begins.

Defrost Control Timing Pins

Each timing pin selection provides a different accu

mulated compressor run period during one thermo

stat run cycle. This time period must occur before a

defrost cycle is initiated. The defrost interval can be

adjusted to 30, 60 or 90 minutes. See figure 9. The de

frost period is a maximum of 14 minutes and cannot

be adjusted. If no timing is selected, the control de

faults to 90 minutes.

A TEST option is provided for troubleshooting. When

the jumper is placed across the TEST pins, the timing of

all functions is reduced by a factor of 128. For example,

a 90 minute interval during TEST is 42 seconds and the

14 minute defrost is reduced to 6.5 seconds.