Page 11

Diagnostic LEDs

The defrost board uses two LEDs for diagnostics. The

LEDs flash a specific sequence according to the

condition.

TABLE 7

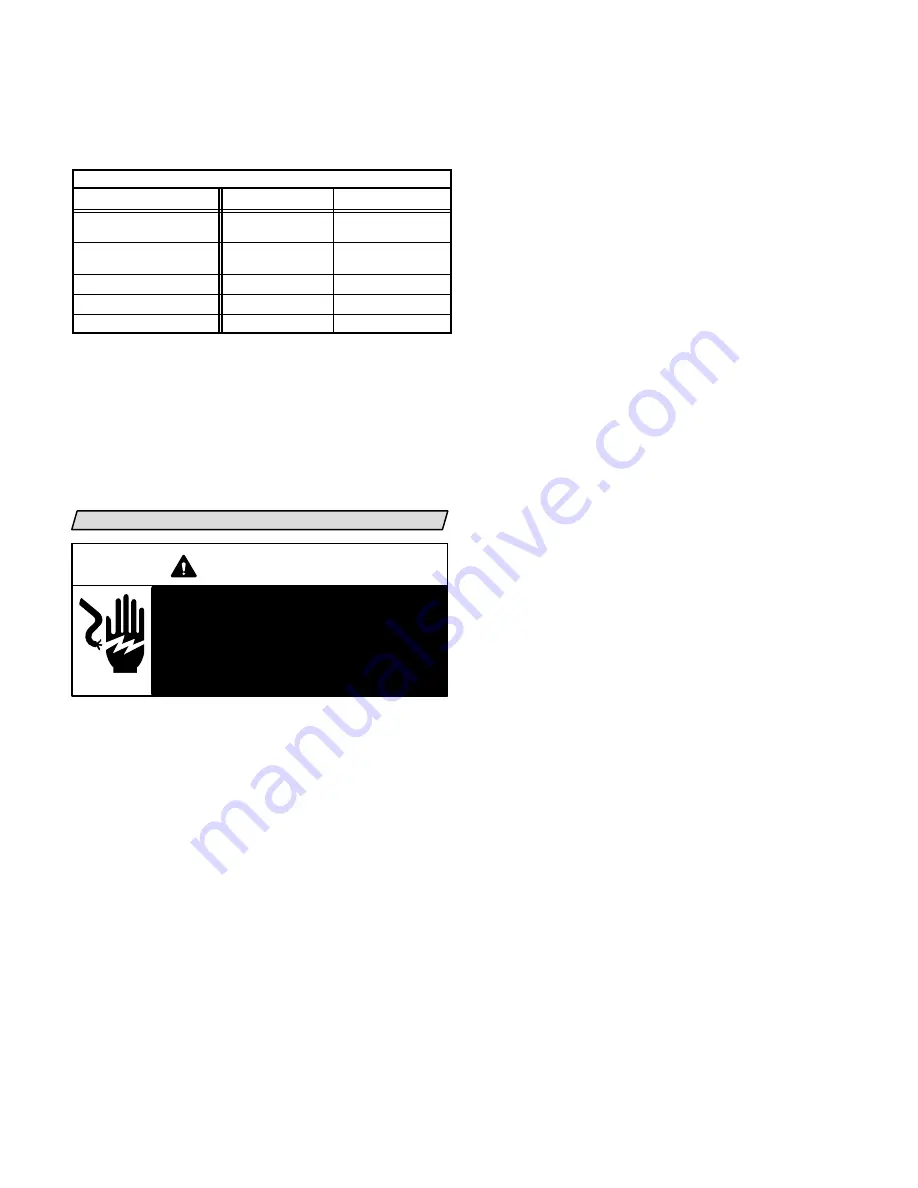

DEFROST CONTROL BOARD DIAGNOSTIC LED

MODE

LED 1

LED 2

Normal Operation/

Power to board

Flash together

with LED 2

Flash together with

LED 1

Time Delay

To Protect Compressor

Alternating Flashes

with LED 2

Alternating Flashes

with LED 1

Pressure Switch Open

Off

On

Pressure Switch Lockout On

Off

Board Malfunction

On

On

Ambient Thermistor & Service Light Connection

The defrost control board provides terminal connec

tions for the ambient thermistor and service light.

These features provide a service light thermostat

which activates the room thermostat service light dur

ing periods of inefficient operation. The thermistor

compensates for changes in ambient temperature

which might cause thermostat droop.

MAINTENANCE

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to per

form any service or maintenance, turn

the electrical power to unit OFF at dis

connect switch(es). Unit may have

multiple power supplies.

At the beginning of each heating or cooling season, the

system should be cleaned as follows:

Heat Pump Unit

1- Clean and inspect outdoor coil. (Coil may be

flushed with a water hose.)

2- Outdoor coil fan motor is prelubricated and

sealed. No further lubrication is needed.

3- Visually inspect all connecting lines, joints and

coils for evidence of oil leaks.

4- Check all wiring for loose connections.

5- Check for correct voltage at unit (unit operating).

6- Check amp-draw on heat pump fan motor.

Unit nameplate_______Actual_______.

7- Inspect drain holes in coil compartment base and

clean if necessary.

NOTE-If insufficient heating or cooling occurs, the unit

should be gauged and refrigerant charge checked.

Indoor Coil

1- Clean coil if necessary.

2- Check connecting lines, joints and coil for evi

dence of oil leaks.

3- Check condensate line and clean if necessary.

Indoor Unit

1- Clean or change filters.

2- Adjust blower speed for cooling. The pressure drop

over the coil should be checked to determine the cor

rect blower air volume. Refer to the Lennox Engi

neering Handbook for indoor unit blower perfor

mance tables.

3- Check all wiring for loose connections.

4- Check for correct voltage at unit.

5- Check amp-draw on blower motor.

Motor nameplate_______Actual_______.