Page 11

IMPORTANT

Use a thermocouple or thermistor electronic vacuum

gauge that is calibrated in microns. Use an instrument

that reads from 50 microns to at least 10,000 microns.

1 − Connect manifold gauge set to the service valve ports :

low pressure gauge to

vapor

line service valve

high pressure gauge to

liquid

line service valve

2 − Connect micron gauge.

3 − Connect the vacuum pump (with vacuum gauge) to the

center port of the manifold gauge set.

4 − Open both manifold valves and start the vacuum

pump.

5 − Evacuate the line set and indoor unit to an

absolute

pressure

of 23,000 microns (29.01 inches of mercu-

ry). During the early stages of evacuation, it is desirable

to close the manifold gauge valve at least once to deter-

mine if there is a rapid rise in

absolute pressure

. A

rapid rise in pressure indicates a relatively large leak. If

this occurs, repeat the leak testing procedure.

NOTE − The term

absolute pressure

means the total

actual pressure within a given volume or system,

above the absolute zero of pressure. Absolute pres-

sure in a vacuum is equal to atmospheric pressure mi-

nus vacuum pressure.

6 − When the absolute pressure reaches 23,000 microns

(29.01 inches of mercury), close the manifold gauge

valves, turn off the vacuum pump and disconnect the

manifold gauge center port hose from vacuum pump.

Attach the manifold center port hose to a nitrogen cylin-

der with pressure regulator set to 150 psig (1034 kPa)

and purge the hose. Open the manifold gauge valves to

break the vacuum in the line set and indoor unit. Close

the manifold gauge valves.

CAUTION

Danger of Equipment Damage.

Avoid deep vacuum operation. Do not use compres-

sors to evacuate a system.

Extremely low vacuums can cause internal arcing

and compressor failure.

Damage caused by deep vacuum operation will void

warranty.

7 − Shut off the nitrogen cylinder and remove the manifold

gauge hose from the cylinder. Open the manifold

gauge valves to release the nitrogen from the line set

and indoor unit.

8 − Reconnect the manifold gauge to the vacuum pump,

turn the pump on, and continue to evacuate the line set

and indoor unit until the absolute pressure does not rise

above 500 microns (29.9 inches of mercury) within a

20−minute period after shutting off the vacuum pump

and closing the manifold gauge valves.

9 − When the absolute pressure requirement above has

been met, disconnect the manifold hose from the vacu-

um pump and connect it to an upright cylinder of R−410A

refrigerant. Open the manifold gauge valves to break

the vacuum from 1 to 2 psig positive pressure in the line

set and indoor unit. Close manifold gauge valves and

shut off the R−410A cylinder and remove the manifold

gauge set.

C − Charging

Charge Using the Weigh-in Method

Outdoor

Temperature < 65ºF (18ºC)

If the system is void of refrigerant, or if the outdoor ambient

temperature is cool, first, locate and repair any leaks and

then weigh in the refrigerant charge into the unit.

1. Recover the refrigerant from the unit.

2. Conduct leak check; evacuate as previously outlined.

3. Weigh in the unit nameplate charge. If weighing facili-

ties are not available or if charging the unit during warm

weather, use one of the following procedures.

Charge Using the Subcooling Method

Outdoor

Temperature < 65ºF (18ºC)

When the outdoor ambient temperature is below 65°F

(18°C), use the subcooling method to charge the unit. If

necessary, restrict the air flow through the outdoor coil to

achieve pressures in the 325−375 psig (2240−2585 kPa)

range. These higher pressures are necessary for checking

the charge. Block equal sections of air intake panels and

move obstructions sideways until the liquid pressure is in

the 325−375 psig (2240−2585 kPa) range. See figure 15.

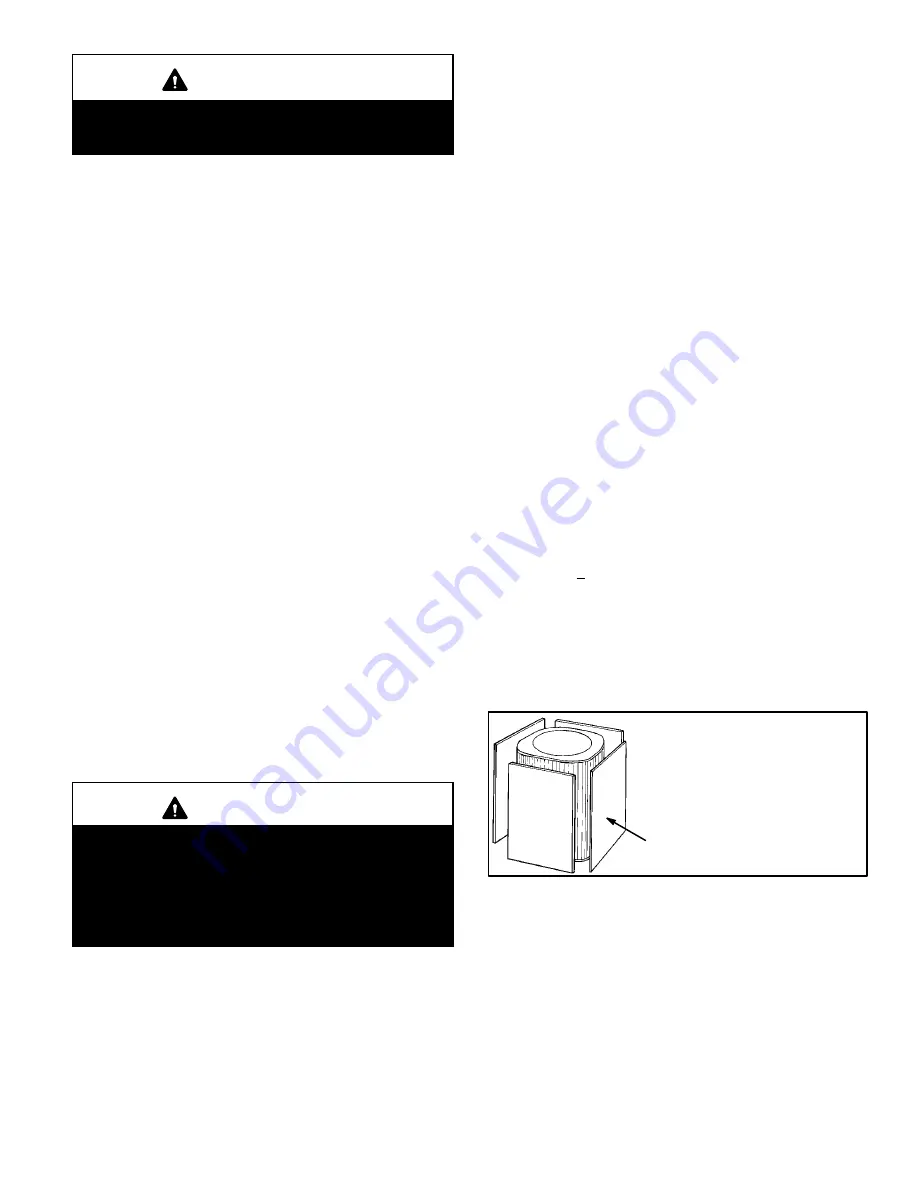

Blocking Outdoor Coil

BLOCK OUTDOOR COIL ONE

SIDE AT A TIME WITH

CARDBOARD OR PLASTIC

SHEET UNTIL PROPER TESTING

PRESSURES ARE REACHED.

CARDBOARD OR PLASTIC

SHEET

FIGURE 15

1. With the manifold gauge hose still on the liquid service

port and the unit operating stably, use a digital ther-

mometer to check the liquid line temperature and re-

cord in table 5.

2. At the same time, record the liquid line pressure reading.

3. Use a temperature/pressure chart for R−410A (table 4)

to determine the saturation temperature for the liquid

line pressure reading; record in table 5.