22

8.2 Wedge Cleaning

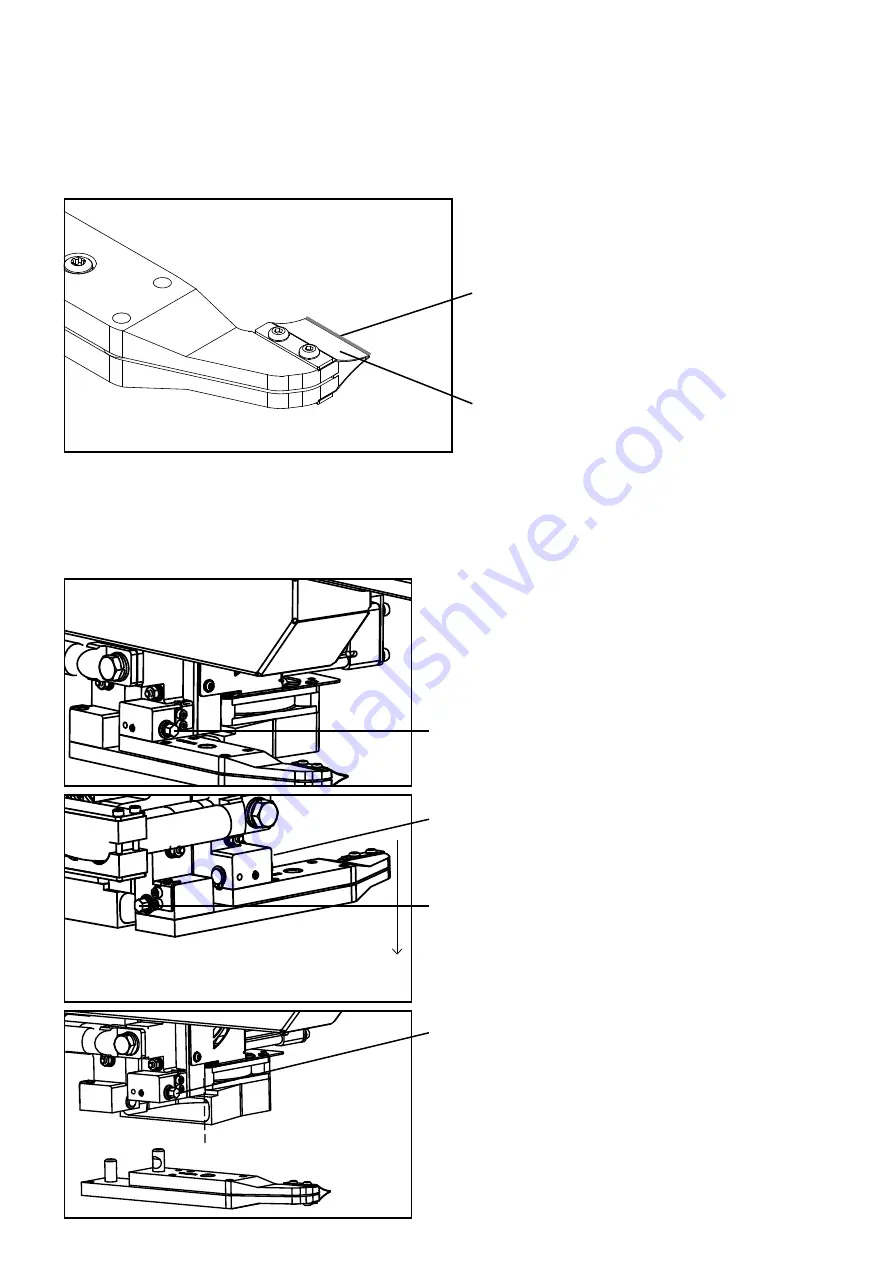

Area of slag formation

22

When the wedge is positioned properly and the welding parameters are set correctly, very little slag is formed. It is

mainly limited to the front part of the wedge (22). If an excessive amount of slag is formed, readjust the wedge and

reduce the energy value.

Clean the wedge at regular intervals to remove slag and impurities. Use a plastic scraper to remove the slag. If the

welding performance deteriorates or mechanical damage occurs, replace the wedge (Chapter 8.5).

The wedge holder must be replaced in the event of damage or if the welding width needs to be changed.

Thanks to the quick-change system, the holder can be replaced quickly and easily. Turn screws 2A and 2B a quar-

ter-turn counterclockwise while holding on to the wedge. The wedge holder can then simply be lowered and removed.

To fit the new wedge holder, insert it from below and

then re-tighten screws 2A and 2B in a clockwise di-

rection.

8.3 Changing the Wedge Holder / Changing the Welding Width

2A

2A

2A

2B