17

7.9 Changing Welding Arm and Welding Arm Options

Caution:

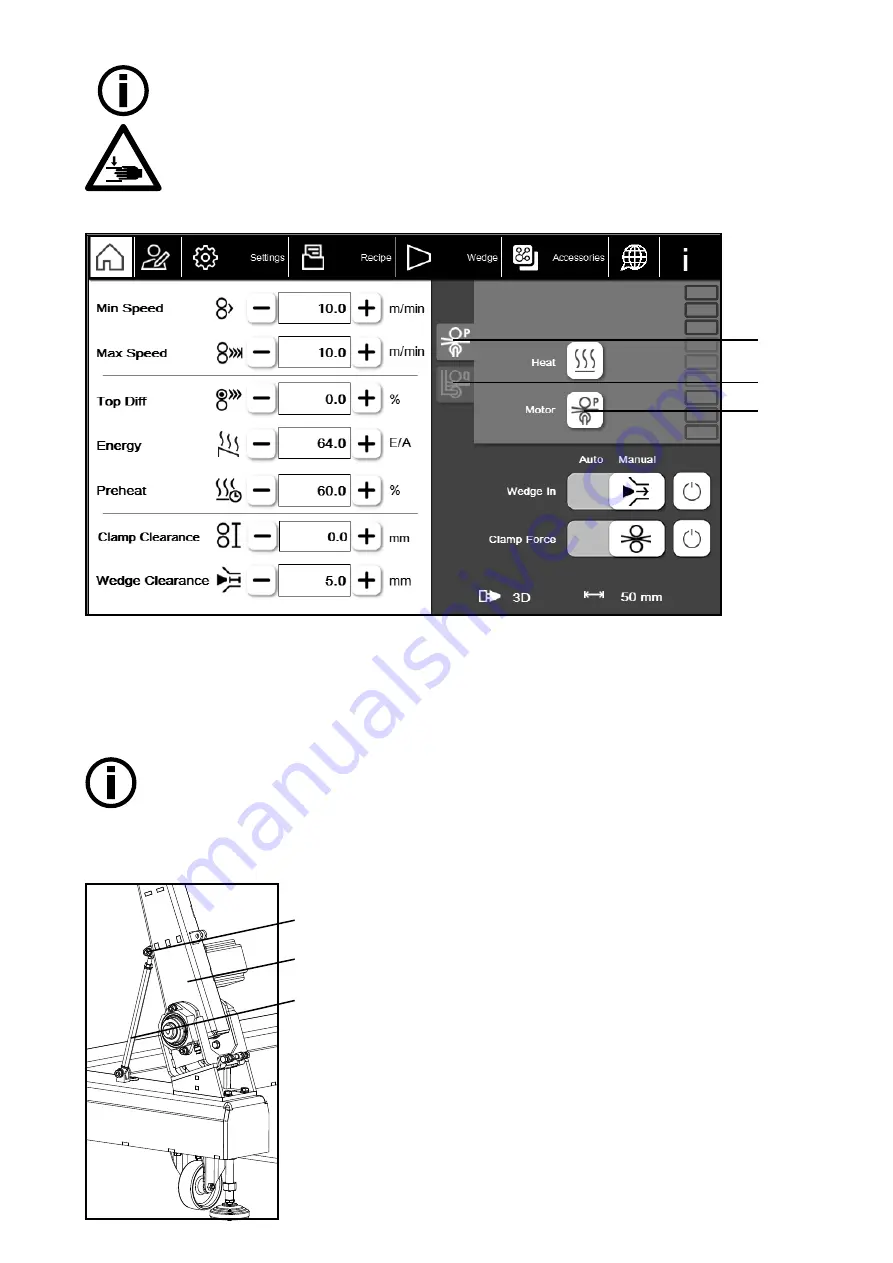

To activate the desired welding arm, the

motor icon (M)

must be switched off.

Make sure that the correct welding arm is selected to prevent damage to the drive and hazardous situa-

tions.

Caution:

Always hold the

pedestal (6)

when you detach the

retaining screw (6A)

. Then carefully lay the pedestal

down. If the pedestal falls downward unchecked, it may sustain irreparable damage.

When folding down the pedestal, be mindful of a possible crushing risk and keep body parts away from the area be-

tween the contact surface and pedestal.

Risk of crushing:

There is a risk of crushing due to the movement of mechanical parts. When changing

the welding arms, make sure that no body parts become trapped. Set the "Wedge In" and "Clamp Force"

sliders to "Manual" to prevent the machine from starting inadvertently.

To change between the individual welding arms, please set all settings to "Manual" and "Off" in advance. The

trans-

port rollers (4)

are now open and the

welding wedge (22)

is in the starting position.

Switch off the motor and select the welding arm you want to activate.

Pedestal (P)

see

Chapter 7.9.2

/

Quickarm (Q)

see

Chapter 7.9.3

Loosen the

screw (6A)

that holds the

threaded rod (6B)

and the

pedestal

(6)

together. Then pull the screw out while firmly holding the pedestal. Care-

fully lay the pedestal down.

Refit the screw and the corresponding washers so they do not get lost.

Now switch to the quickarm.

To bring the pedestal into the welding position, lift the

pedestal (6)

upward

and insert the screw.

7.9.1 Changing Welding Arm

7.9.2 Pedestal

Activating / Deactivating the Pedestal

6A

6

6B

P

Q

M