Leister Technologies AG

Operating Manual

Welding Machine SEAMTEK 36

Revision: A

QM

Page

42 / 62

Created

04.04.2014 TEX

Released

Modified

42

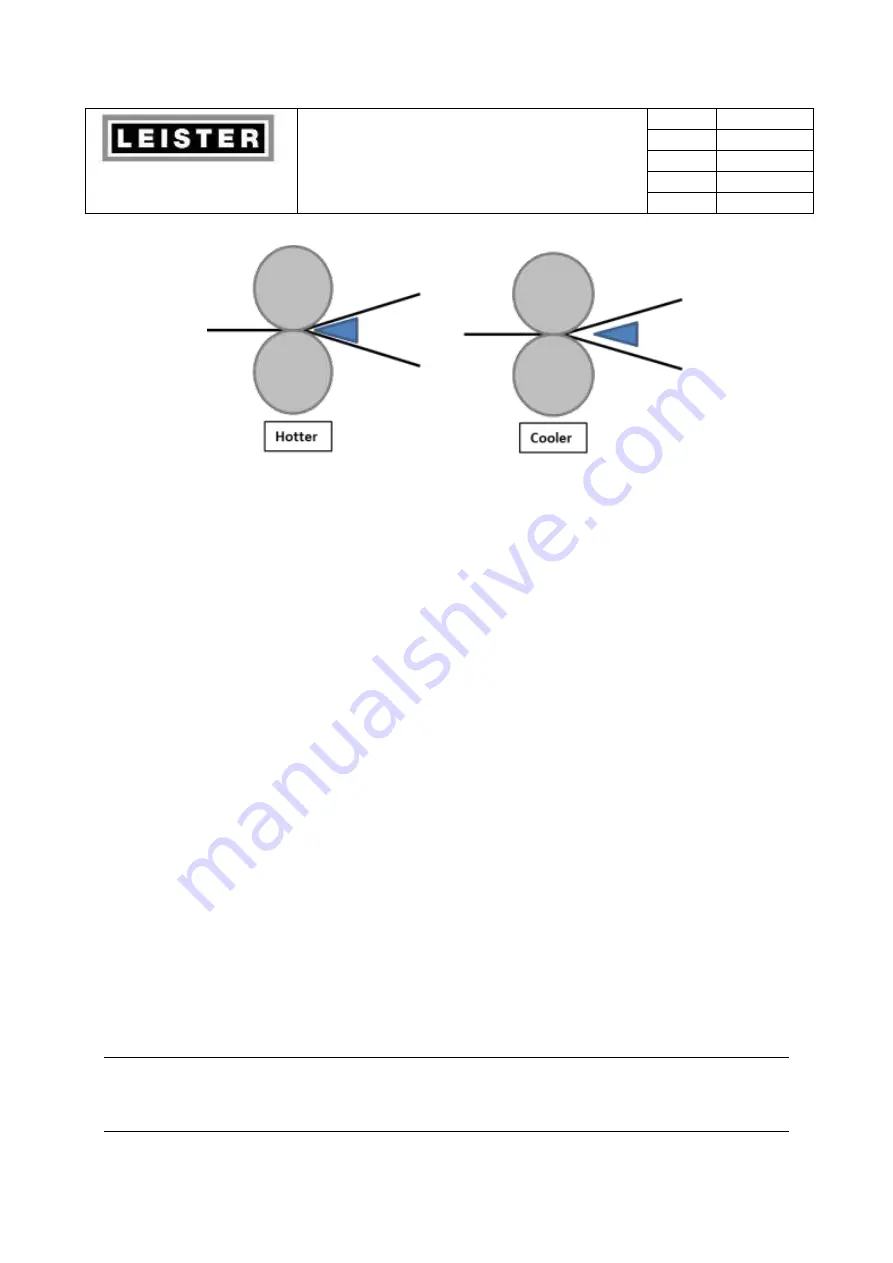

Figure 24 Fabric angle

7.4 Welding a Typical Seam

Using one or both of the two test strip modes, you have determined the correct temperature

and wheel speed combination. You are now ready to weld a seam.

Follow these steps:

1.

To weld a typical seam, make sure the Status Screen is being displayed.

2.

Next, align the two fabric pattern pieces between the wheels as described in Placing Fabric

in the Weld Head (Section 7.1). Hold the two fabric pieces apart so the nozzle can easily

slide between them.

If pre-heat is set at 0, the drive wheels begin rotating at the preset base speed, pulling the

fabric pieces past the weld nozzle and through the wheels where pressure is applied.

3.

Now press the lower-right WELD START/STOP foot pedal switch

.

This brings the nozzle into position between and in front of the two wheels and applies

weld pressure.

4.

Wait a short period of time for the fabric surface to heat sufficiently before you start

welding, typically about 1/2 second or less, then release your foot from the lower-right

WELD START/STOP foot pedal switch.

Set pre-heat

allowing the computer to control this

delay time.

Note

: Set pre-heat. The half-second delay is OK to heat most fabric surfaces; however, very

lightly coated fabrics will require that the wheels start almost as soon as the nozzle is in position