8. Position the burner tray into the box in order to determine the length of 8mm

gas supply needed and cut to length.

9. Before making the final connection, thoroughly purge the supply pipe

to clear any foreign matter, i.e. masonry dust etc, as this could lead to

blockages in the control valve and/or pilot assemblies.

10. Fix the burner in place using the four screws and make the gas

connection. Carry out a gas soundness test.

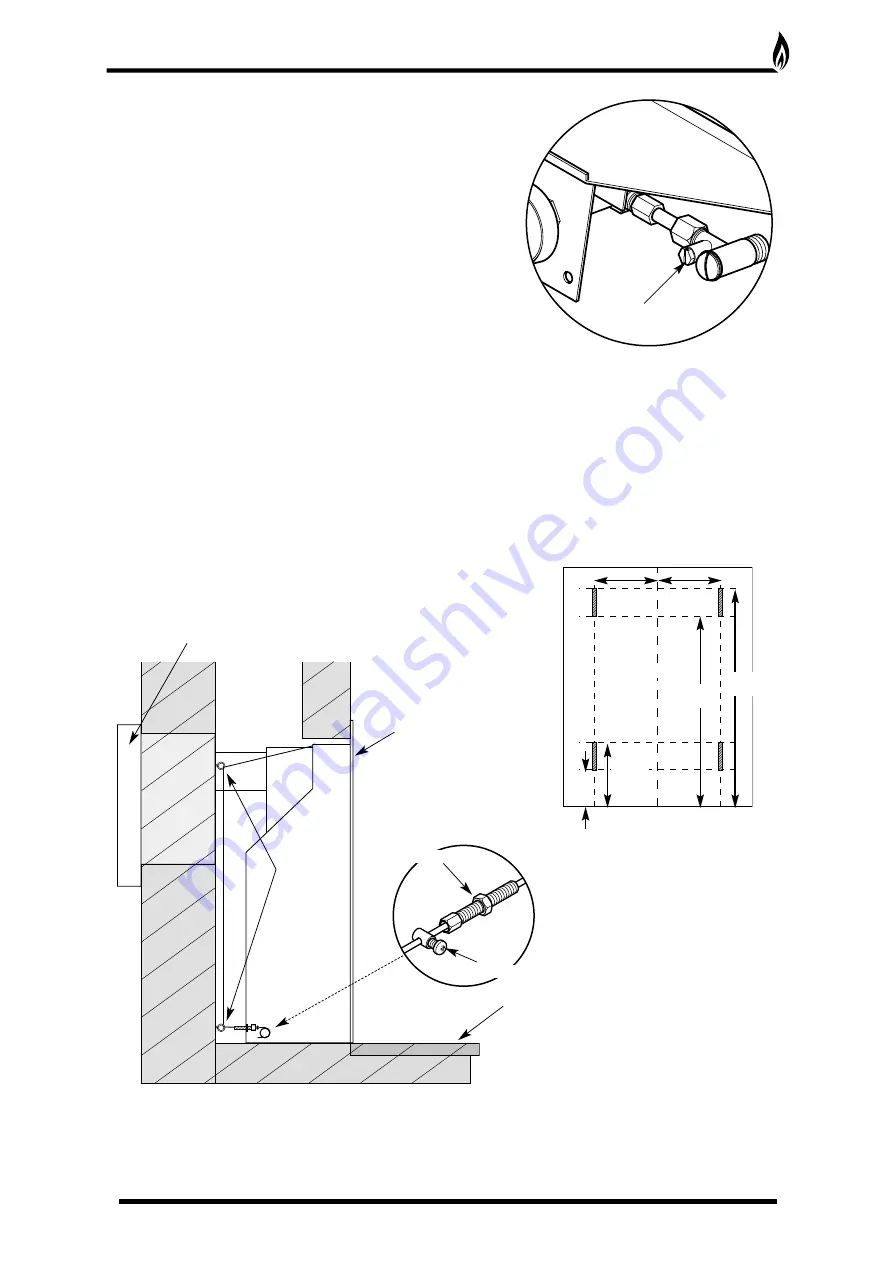

11. Unscrew the pressure test point sealing screw (Fig. 10) and fit a

manometer. Consult the user instructions (page 14). Ignite the

appliance and turn to the high position.

12. Take a pressure reading and consult the technical data (page 11) to

establish the correct working pressure.

13. Once the pressure has been checked and verified, turn off the appliance. Consult the ceramic component set

up diagrams (page 16 - 21) and fit the ceramics as per the instructions.

14. Carry out a Spillage Test.

ALTERNATIVE FIXING METHOD

Where the drilling of the back panel is not practical, an alternative fixing method may be employed using the

cable fixing kit provided. Drill four holes in the rear of the fireplace opening (Fig. 11). Securely fix the four eye

bolts provided using suitable rawl plugs. Feed one cable through each of the top holes in the rear of the

fire box.

Fix the radiant box into the opening, securing into position using the cable fixing kit (Fig. 12). Do not cut off the

loose ends as the full length is required should the radiant box need refitting at any time. Coil up and securely

store underneath the burner tray.

INSTALLATION PROCEDURE

CONTINUED

10

Centre Line

Drill Holes for 4 eye bolts

on 112mm centre lines

between max and min height.

65mm

min

115mm

max

500mm

min

550mm

max

112mm

112mm

Fig. 11

Radiant box

Outer fan cover

Hearth

Eye Bolts

Tension Nut

Cable Clamping Screw

Fig. 12

Fig. 10

Pressure Test Point