PLMNL0232 REV. H Effective Date: 01/14/19

53

FiberCUT

®

2D Operation Manual

7 Troubleshooting

SYMPTOM

CAUSE

REMEDY

HSU Fault:

1: Tip Open

There is no connection between the HSU

and tip assembly during calibration.

Verify that the tip assembly and

internal sense cables are properly

installed and then recalibrate.

HSU Fault:

2: Tip Shorted

The tip is not fully insulated from ground

and the body of the cutting head during

calibration.

Remove any debris that may be

causing a short and then

recalibrate.

HSU Fault:

3: Cable Break

The connection between the HSU and tip

has been broken.

Verify that the tip assembly and tip

are properly installed and then

recalibrate.

HSU Fault:

5: Curve Data Error

There is no curve data in the selected

location or the data failed to load correctly.

Load the curve data again or

select a different curve number.

HSU Fault:

6: Invalid curve

number

The value in the Set HSU Curve Industrial

Ethernet register is outside the allowed

range

(1-31).

Enter a valid number or 0 to idle

the input.

HSU Fault:

7: Failed to set

curve

The HSU did not respond successfully to a

value change in the Set HSU Curve

Industrial Ethernet register.

Attempt to set the curve again by

setting the value to 0 and then to

the new curve number.

Verify the head and HSU are

properly connected.

Lens Fault

The lens was out of the commanded

position for an excessive amount of time.

Activate the

Reset

bit or button to

re-establish the zero position of

the motor.

The motor may have stalled or lost its zero

position.

Verify the motor is connected.

Purge Fault

The purge pressure is too low or too high.

Verify the purge gas is turned on

and properly regulated.

Expand the allowable range by

lowering or raising limits.

Temperature Fault

The temperature of one or more sensors

has exceeded the limit.

Allow the component to cool.

Consider raising the temperature

limit if it is safe.

A cover glass drawer has been removed.

Verify the drawers are fully

inserted and the doors are latched

securely.

A temperature sensor is disconnected.

Check the internal cable

connections.

Position Error

The Move Lens command could not be

completed because the value in the Set

Position Industrial Ethernet register is

above the Maximum Position or a Lens

Fault exists.

Clear the

Move Lens

bit. Activate

the

Reset

bit if necessary. Enter a

value that is less than or equal to

the Maximum Position and set the

Move Lens

bit again.

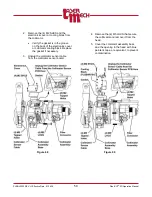

Continuity between

the upper plate and

tip

Tip Retainer Assembly assembled

incorrectly or damaged

Repair or replace the tip retainer

assembly according to

Purge Fault

Incorrect zero pressure point

Activate the

Zero Pressure

bit