34

Section 4: Maintenance & Lubrication

8/15/12

RCR3596, RCRM3596, RCR3510 & RCRM3510 Rotary Cutters 312-517M

Table of Contents

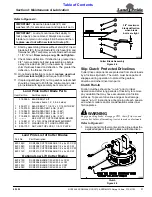

Flex Couplers

Refer to Figure 4-8:

Replace two rubber discs (#1) as follows: (Land Pride

Part No. 1785273) as follows: Refer to land Pride’s Parts

Manual 312-708P if additional repair parts are required.

1.

Insert three bolts (#3) through the holes in flange

weldment (#7).

2.

Place beaded washers (#2) over the three bolts with

bead facing rubber disc (#1).

3.

Place bushings (#6), rubber disc (#1), washers (#5),

2nd rubber disc (#1), 2nd bushing (#6) and 2nd

washer (5) over the three bolts as shown.

4.

Secure with nuts (#4). Do not tighten.

5.

Insert three bolts (#3) through holes in flanged hub

(#8).

6.

Repeat steps 2 through 4.

7.

Tighten nuts (#4) evenly with nuts torqued 35 to

40 ft-lb. Beaded washers (#2) should be imbedded

halfway into the rubber disc.

Flex Couplers

Figure 4-8

Long Term Storage

Clean, inspect, service, and make necessary repairs to

the cutter when parking it for long periods and when

parking it at the end of a working season. This will help

ensure the cutter is ready for field use the next time you

hook-up to it.

!

DANGER

Always disconnect main driveline from tractor PTO shaft

before servicing drive train components and cutter blades.

The PTO can be engaged if tractor is started causing bodily

injury or death.

!

DANGER

Always secure cutter deck in the up position with solid

supports before servicing underside of cutter. Never work

under equipment supported by hydraulics. Hydraulics can

drop equipment if controls are actuated or if hydraulic lines

burst. Either situation can drop the cutter instantly even when

power to the hydraulics is shut off.

14560

!

CAUTION

Always store cutter with 3-Point hitch pivoted back as far as

possible. The floating 3-Point hitch when not hooked to a

tractor can fall backwards unexpectedly causing bodily injury.

1.

Clean off any dirt and grease that may have

accumulated on the cutter and moving parts. Scrape

off compacted dirt from the bottom of deck and then

wash surface thoroughly with a garden hose. A

coating of oil may also be applied to the lower deck

area to minimize oxidation.

2.

Check blades and blade bolts for wear and replace if

necessary. See “Cutter Blade Maintenance” on

page 30.

3.

Inspect for loose, damaged or worn parts, and adjust

or replace as needed.

4.

Repaint parts where paint is worn or scratched to

prevent rust. Ask your Land Pride dealer for aerosol

touch-up paint. They are also available in touch-up

bottles with brush, quarts, and gallon sizes by adding

TU, QT, or GL to the end of the aerosol part number.

5.

Replace all damaged or missing decals.

6.

Lubricate as noted in “Lubrication” on page 35.

7.

Store cutter on a level surface in a clean, dry place.

Inside storage will reduce maintenance and make for

a longer cutter life.

8.

Follow all unhooking instructions on page 28 when

disconnecting tractor from cutter.

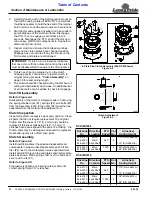

Ordering Replacement Parts

Land Pride offers equipment in factory standard beige

color with black highlights. Equipment in special colors

may be purchased in Green, Red or Orange. Because of

the variety of colors available, special attention must be

given to the part number to prevent ordering the wrong

replacement part. A suffix number corresponding to one

of the colors below must be added at the end of Land

Pride’s part number when ordering a replacement part

with that color. Parts ordered without a suffix number will

be supplied in factory standard colors.

For example, if you are ordering a replacement part with

part number 555-555C and the existing part is red, then

add the suffix 83 to the end of the number to make the

part number read 555-555C83.

Land Pride Touch-up Paints

Part No.

Part Description

821-011C

PAINT LP BEIGE SPRAY CAN

821-002C

PAINT GP BLACK SPRAY CAN

821-054C

PAINT MEDIUM RED SPRAY CAN

821-058C

PAINT GREEN SPRAY CAN

821-066C

PAINT ORANGE AEROSOL SPRAY CAN

81 . . . . . . Green

82 . . . . . . Orange

83 . . . . . . . Red

85 . . . . . . . Black