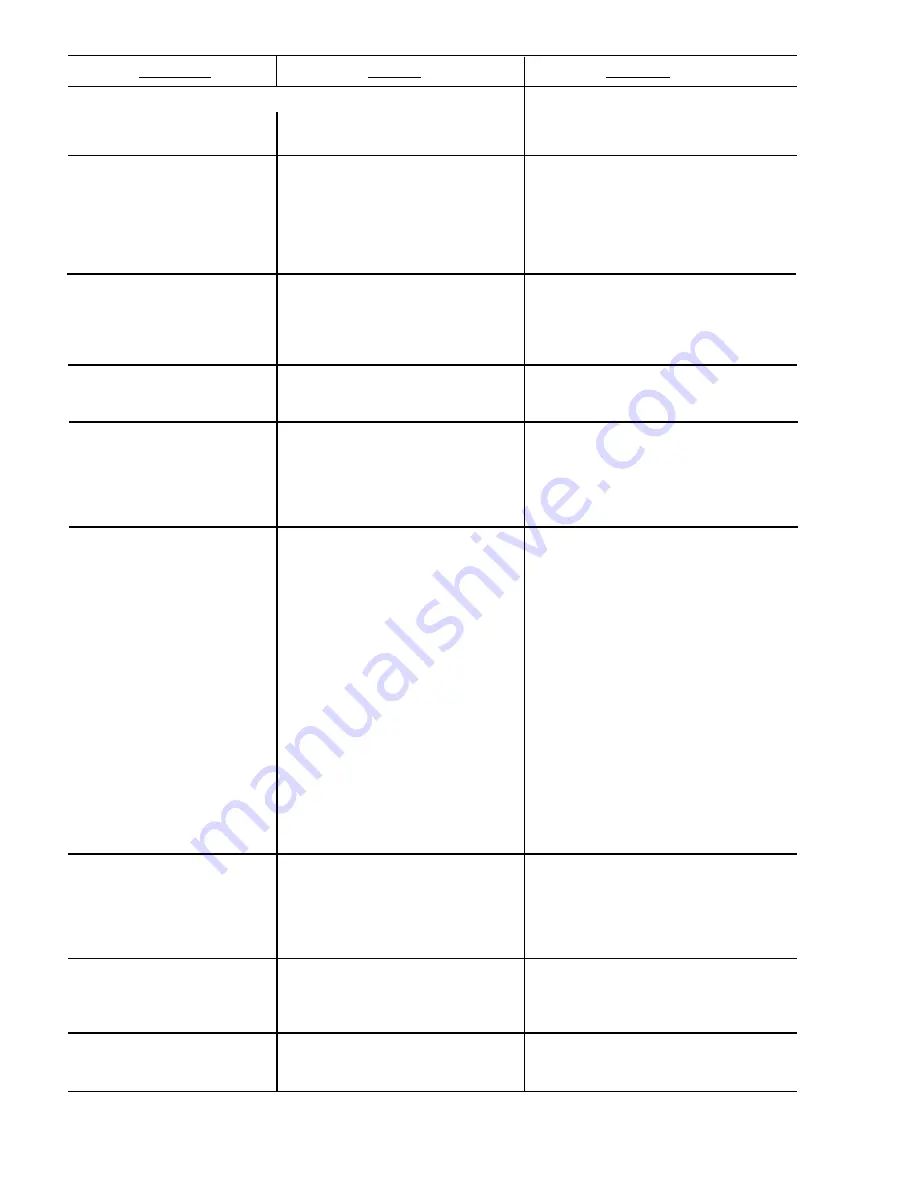

Section 8.17 continued from previous page.

F. Refrigerant leak.

F. Repair and recharge.

G. Compressor malfunctioning.

G. Replace compressor.

8.18

Compressor runs

A. Low water level in water

A. Add water to water bath until water

normally, but water

bath.

runs out of overflow into drip tray.

line is frozen.

B. Syrup in water bath.

B. Drain water from water bath and

refill with clean water.

C. Water cage is out of position.

C. Reposition water cage.

D. Low refrigerant charge/slow

D. Find and repair leak. Recharge

refrigerant leak

system.

8.19

Compressor cycles

A. PCB malfunctioning

A. Replace PCB assembly.

on and off frequently

B. Defective probe.

B. Replace probe.

during the initial

C. Air flow blocked.

C. Check to ensure proper air

pulldown and/or

clearance is provided (see

normal operations.

Section 1.4).

8.20

Plain water flow is

A. Insufficient incoming supply

A. Verify incoming supply water

insufficient.

water and/or pressure.

pressure is a minimum of zero (0)

PSI flowing.

8.21

Suspect faulty PCB.

A. PCB not receiving proper

A. Check power from transformer on

input voltage.

pins 4 and 5 of J10.

B. Green light not flashing (off

B. Replace PCB.

or continuously on).

C. Yellow lights off and green light C. Check fuses F1 and F2, and also

is on when key switch is on.

connection at J10.

8.22

Circuit breaker tripping.

A. Pump is shorted.

A. Disconnect pump and restore

power. If breaker does trip, then

pump is OK. If breaker does not

trip, replace pump.

B. Refrigeration relay is bad.

B. Detect short by disconnecting J10

connector (24VAC input) from

PCB. Restore power. If breaker

doesn’t trip, then replace

refrigeration relay. If breaker does

trip, then refrigeration relay is OK.

Reconnect J10 connector.

C. Secondary wire harness is

C. Detect short by disconnecting both

bad.

secondary transformer fastons and

restore power. If it does not trip,

locate short in secondary harness

between transformer and PCB.

D. Transformer failure.

D. Detect short by disconnecting both

primary transformer fastons and

restore power. If breaker doesn’t

trip, replace transformer.

8.23

BIB pump does not

A. Out of CO

2

, CO

2

not turned

A. Replace CO

2

supply, turn on CO

2

operate when

on, or low CO

2

pressure.

supply, or adjust CO

2

pressure to

dispensing valve is

70-80 PSI.

opened.

B. Out of syrup.

B. Replace syrup supply.

C. BIB connector not tight.

C. Fasten connector tightly.

D. Kinks in syrup or gas lines.

D. Straighten or replace lines.

8.24

BIB pump operates but

A. Leak in syrup inlet or outlet

A. Replace line.

no flow.

line.

B. Defective BIB pump check

B. Replace BIB pump.

valve.

8.25

BIB pump continues to

A. Leak in suction line.

A. Replace line.

operate when bag is

B. Leaking o-ring on pump inlet

B. Replace o-ring.

empty.

fitting.

15

TROUBLE

CAUSE

REMEDY