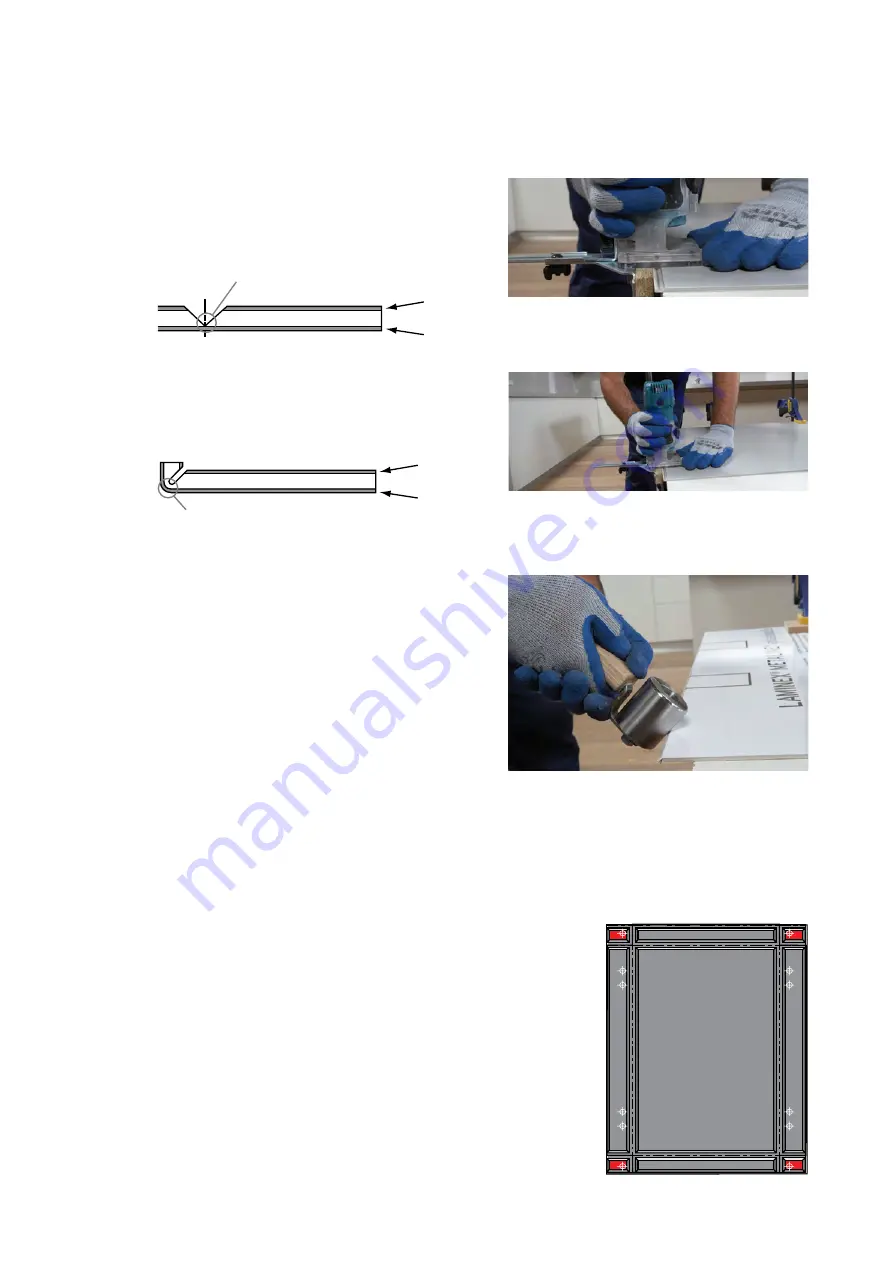

3.1.3 Fabrication Type – Folded Rolled Edges

Preferred Method:

Folded rolled edges give a completely encapsulated finish to the sheet, which hides

the core of the panel from view.

3.1.4 Fabrication Type – Finished Corner Details

Where the sheet requires two rolled edges to meet on corners, the following

method is used to allow for the edge folds to encapsulate the core:

X

Y

X

Y

X - 6mm

Y - 6mm

X - 6mm

Back Face

Front Face

Y - 6mm

Back Face

Front Face

X + 6mm

Back Face

Front Face

Y + 6mm

Back Face

Front Face

X - 6mm

Y - 6mm

Back Face

Double Sided Tape

Front Face

X

Y

X + 6mm

Y + 6mm

Back Face

Front Face

Back Face

Front Face

X + 6mm

Y + 6mm

Back Face

Front Face

Double Sided Tape

Some core must remail in routered channel

(maximum 1mm)

X

Y

X

Y

X - 6mm

Y - 6mm

X - 6mm

Back Face

Front Face

Y - 6mm

Back Face

Front Face

X + 6mm

Back Face

Front Face

Y + 6mm

Back Face

Front Face

X - 6mm

Y - 6mm

Back Face

Double Sided Tape

Front Face

X

Y

X + 6mm

Y + 6mm

Back Face

Front Face

Back Face

Front Face

X + 6mm

Y + 6mm

Back Face

Front Face

Double Sided Tape

Some core must remail in routered channel (maximum 1mm)

1. Router the back of the sheet as per

previous detail for rolled edges allowing

the two passes to criss-cross over the

corner edge.

2. Remove the section of material as shown

in red using a sharp chisel.

3. Roll the two sections over and the corner

should meet without any overlap.

1. Allowance is made for the edge fold in

the measurement as per below:

2. Panels are rebated behind the edge fold

section to allow for the panel to be rolled

over, giving the following finished edge

detail:

3. The slight overlap of the fold is

retained to allow for the thickness of

the double sided tape and silicone

fastening to the wall.

4. This method is ideally suited to

installations where more than one

sheet is required to span the wall. It

gives a premium join appearance by

concealing the cut edge of the sheet.