LAARS Heating Systems

Page 16

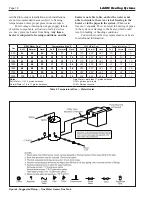

Size

20°F

(11°C)

25°F

(14°C)

30°F

(17°C)

35°F

(19°C)

gpm

lpm

gpm

lpm

gpm

lpm

gpm

lpm

500

43

161

34

129

26

107

24

92

750

64

241

51

193

43

161

36

138

1000

85

321

68

257

57

214

49

184

1250

106

401

85

322

71

269

61

231

1500

128

483

102

386

85

322

73

276

1750

N/R

N/R

119

451

99

375

85

322

2000

N/R

N/R

103

515

113

429

97

368

Notes:

gpm = gallons per minute,

lpm = liters per minute

,

Maximum temperature rise is 35°F (19°C), as shown.

N/R = not recommended.

Table 8. Temperature Rise - Boiler.

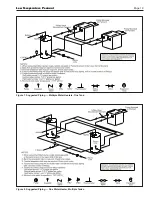

SECTION 4A.

Water Connections —

Pennant Boiler

4A.1 Heating System Piping:

Hot Supply Connections — Boiler

NOTE:

This appliance must be installed in a closed

pressure system with a minimum of 12 psig (82.7

kPa) static pressure at the boiler.

Hot water piping should be supported by suitable

hangers or floor stands. Do not support piping with

this appliance. Due to expansion and contraction of

copper pipe, consideration should be given to the type

of hangers used. Rigid hangers may transmit noise

through the system resulting from the piping sliding in

the hangers. It is recommended that padding be used

when rigid hangers are installed. Maintain 1" clearance

to combustibles for hot water pipes.

Pipe the discharge of the relief valve (full size)

to a drain or in a manner to prevent injury in the event

of pressure relief. Install an air purger, an air vent,

a diaphragm-type expansion tank, and a hydronic

flow check in the system supply loop. Minimum fill

pressure must be 12 psig (82.7 kPa). Install shutoff

valves where required by code.

See suggested piping diagrams (

Figures 4-5).

These diagrams are meant only as a guide. Com pon-

ents required by local codes must be properly installed.

Note the recommended location of the

temperature sensor on the diagrams; you must provide

a location for the additional sensor shipped with the

Pennant. This sensor may be strapped onto pipe from

1" to 4" diameter, or inserted into an immersion well.

4A.2 Cold Water Make-Up — Boiler

1. Connect the cold water supply to the inlet

connection of an automatic fill valve.

2. Install a suitable back flow preventer between the

automatic fill valve and the cold water supply.

3. Install shut off valves where required.

NOTE:

The boiler, when used in connection with a

refrigeration system, must be installed so the chilled

medium is piped in parallel with the boiler with

appropriate valves to prevent the chilled medium from

entering the boiler.

The boiler piping system of a hot water heating

boiler connected to heating coils located in air

handling appliances where they may be exposed to

refrigerated air circulation must be equipped with flow

control valves or other automatic means to prevent

gravity circulation of the boiler water during the

cooling cycle.

A boiler installed above radiation level, or as

required by the authority having jurisdiction, must be

provided with a low water cutoff device either as a part

of the boiler or at the time of boiler installation.

4A.3 Water Flow Requirements — Boiler

Low Temperature Pennant Boilers are equipped

with a mounted pump. The pumps are sized for the

boiler’s head loss and 30 feet of full-size piping (same

size as boiler outlet), with a normal number of fittings.

The boilers must be piped in a primary-secondary sys-

tem, such that the boiler’s pump only serves the boiler.

Figures 4 and 5

show examples of this type of piping.

The minimum inlet water temperature to the

Pennant is 70°F (20°C). The mixing system on the

Pennant will ensure that the heat exchanger in the

Pennant does not see water that is less than 120°F

(49°C), so that excessive condensation does not form

on the heat exchanger.

Table 8

shows a relationship between water flow

through the boiler and the temperature difference (rise)

between the inlet and outlet of the boiler. This table

will enable the user to test the boiler for proper water

flow. Since the boiler has a mixing system that sends

a portion of the hot water from the boiler outlet to the

boiler inlet, the water flow coming out of the mixing

system will vary, depending on the return water

temperature.

4A.4 Freeze Protection — Boiler

Boiler installations are not recommended in

areas where the danger of freezing exists unless proper

precautions are made for freeze protection. A non

toxic, heating system, anti-freeze may be added to the

hydronic system provided that the concentration does

not exceed 50% and the anti freeze contains an anti

foamant. Power outage, interruption of gas supply,

failure of system components, activation of safety

devices, etc., may prevent a boiler from firing.

Any

time a boiler is subjected to freezing conditions,

and the boiler is not able to fire, and/or the water

is not able to circulate, there is a risk of freezing in

the boiler or in the pipes in the system.

When water

freezes, it expands. This can result in bursting of pipes

in the system, or damage to the boiler, which could

result in leaking or flooding conditions.

IMPORTANT NOTES:

Different glycol products may

provide varying degrees of protection. Glycol products

must be maintained properly in a heating system, or

they may become ineffective. Consult the glycol speci-

fications, or the glycol manufacturer, for information

about specific products, maintenance of solutions, and

set up according to your particular conditions. Never

use

ethylene

glycol (automotive antifreeze).

Summary of Contents for Pennant PNCH

Page 23: ...Low Temperature Pennant Page 23 Figure 12 Ladder Diagram Sizes 500 1000 ...

Page 24: ...LAARS Heating Systems Page 24 Figure 13 Ladder Diagram Sizes 1250 2000 ...

Page 25: ...Low Temperature Pennant Page 25 Figure 14 Wiring Diagram Sizes 500 1000 ...

Page 26: ...LAARS Heating Systems Page 26 Figure 15 Wiring Diagram Sizes 1250 1500 ...

Page 27: ...Low Temperature Pennant Page 27 Figure 16 Wiring Diagram Sizes 1750 2000 ...