LAARS Heating Systems

Page 30

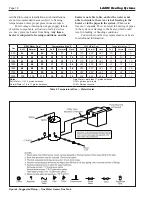

oAH – Maximum Setpoint

This is the maximum allowable calculated

setpoint, regardless of outdoor temperature.

Default is 190°F. Range is 90°F to 210°F.

rc – Reset Ratio

The ratio of air temperature movement to water

temperature movement. Sets the slope of the reset

curve. Default is 1.0. Range is from 0.5 to 5.0.

SP – Minimum Mixed Temperature

This setting is fixed at 125°F, and cannot be

change by the user.

Pd – Pump Delay

This is the time delay for the boiler’s mounted

pump. The pump will run for this delay time after

the call for heat has ended. Default is 2 minutes.

Range is from 0.1 minutes to 10 minutes.

Uni - Units

This allows the user to choose between °F

(default) and °C.

6.3.3 Programming Parameters – Water

Heaters

When the control is first turned on, it flashes

“ZZZ” and then “018” to indicate that the boiler

software is in the control. When the down arrow is

pressed, the boiler menu is brought up.

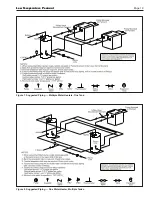

rT – Heater Return Temperature

This is a display only. This is the temperature

at the heater’s inlet sensor. This is not system

return temperature, as the water has been mixed

with hot outlet water, for heater protection.

bSP – Heater Setpoint

This is the setpoint for rT (the heater inlet

temperature sensor). Default is 140°F. Range is

from 140°F to 190°F.

LSP – System Setpoint

This is the setpoint for system, read at the system

sensor that is placed in the system loop. Default

is 140°F. Range is from 60°F to 190°F.

LdF – System Setpoint Differential

This is the differential for LSP. Default is 2.0°F.

Range is 1°F to 30°F.

Pd – Pump Delay

This is the time delay for the heater’s mounted

pump. The pump will run for this delay time after

the call for heat has ended. Default is 2 minutes.

Range is from 0.1 minutes to 10 minutes.

SP – Minimum Mixed Temperature

This setting is fixed at 125°F, and cannot be

change by the user.

bdf – Heater Setpoint Differential

This is the differential for bSP. Default is 10°F.

Range is 1°F to 30°F.

Uni - Units

This allows the user to choose between °F

(default) and °C.

CAUTION

Should overheating occur or the gas supply fail to

shut off, turn off the manual gas control valve to the

appliance.

6.4 Limit Controls

Pennant appliances are fitted with an automatic

reset high limit and a manual reset high limit, both

sensing the outlet temperature of the Pennant.

Water heater high limits are adjustable up to

200°F (93°C) and boiler high limits are adjustable up

to 240°F (116°C).

To set the limit controls, remove the control

panel cover and pull the control panel out to gain

access.

6.5 Operating the Burner and Set Up

6.5.1 Set Up for 0 to 2500 Feet Altitude

The Pennant appliance utilizes a modular design

to achieve its stage-firing. The setup must be checked

before the unit is put in operation. Problems such as

failure to start, rough ignition, strong exhaust odors,

etc. can be due to improper setup. Damage to the

Pennant resulting from improper setup is not covered

by the limited warranty.

1. Using this manual, make sure the installation

is complete and fully in compliance with the

instructions.

2. Determine that the appliance and system are

filled with water and all air has been bled from

both. Open all valves.

3. Observe all warnings on the Operating

Instructions label and turn on gas and electrical

power to appliance.

4. Switch on the appliance power switch located on

the right side of the unit.

5. The Pennant will enter the start sequence, as long

as the unit is being called for heat. The blower

and pump come on for pre-purge, then the ignitor

warm-up sequence starts and after the ignitor

warm-up is complete and all safety devices are

verified, the gas valves open. If ignition doesn’t

occur, check that there is proper gas supply.

Wait 5 minutes and start the unit again. During

initial start up, air in the gas line may cause the

Pennant to “lock out” during the first few trials

for ignition. Depending on the ignition modules

installed, the manual reset button on the ignition

modules may need to be depressed to restart the

Pennant.

6. When the unit is running, the supply gas pressure

must be checked. Inlet gas pressure must not

exceed 13” W.C. (3.2kPa). The minimum inlet

gas pressure is 5” W.C. (1.2kPa).

7. Once the inlet gas pressure is verified, the

outlet gas pressure from each valve (manifold

gas pressure) must be checked, and adjusted, if

Summary of Contents for Pennant PNCH

Page 23: ...Low Temperature Pennant Page 23 Figure 12 Ladder Diagram Sizes 500 1000 ...

Page 24: ...LAARS Heating Systems Page 24 Figure 13 Ladder Diagram Sizes 1250 2000 ...

Page 25: ...Low Temperature Pennant Page 25 Figure 14 Wiring Diagram Sizes 500 1000 ...

Page 26: ...LAARS Heating Systems Page 26 Figure 15 Wiring Diagram Sizes 1250 1500 ...

Page 27: ...Low Temperature Pennant Page 27 Figure 16 Wiring Diagram Sizes 1750 2000 ...