LAARS Heating Systems

Page 8

linear run. Subtract 10 allowable linear feet (3.0m) for

every additional elbow used (see

Table 2

). When fewer

than 3 elbows are used, the maximum linear pipe

length allowed is still 50 feet (15.2m).

The connection for the intake air pipe is on the

filter box. Pennant appliances may have venting and

combustion air ducting attached to the top or the back.

They are shipped with the connections at the top. For

attaching either or both pipes to the back, the mounting

flanges are reversible by removing the mounting

screws and orienting the flanges in the desired

position. Replace the screws after positioning flanges.

Run a bead of silicone around the collar and slide the

pipe over the collar. Secure with sheet metal screws.

In addition to air needed for combustion, air

shall also be supplied for ventilation, including all air

required for comfort and proper working conditions

for personnel. The Pennant loses less than 1 percent of

its input rating to the room, but other heat sources may

be present.

2.2 Venting

2.2.1 Vent Categories

Depending upon desired Pennant venting, it may

be considered a Category I or a Category III appliance.

In general, a vertical vent system will be a Category

I system. However, in rare instances, a Pennant’s

vertical vent system may be considered Category

III. In the U.S., the National Fuel Gas Code (ANSI

Z223.1), or in Canada the Natural Gas and Propane

Installation Code (CSA B149.1), defines a Category I

vent system, and includes rules and tables to size these

vent systems. If the Pennant’s vertical vent system

does not satisfy the criteria for Category I venting, it

must be vented as a Category III system.

All Pennant vent systems which discharge

horizontally (without the use of a power venter) are

considered Category III vent systems.

2.2.2 Category I Vent

When vented as a Category I appliance, the

vent system must conform to the National Fuel Gas

Code (ANSI Z223.1-Latest Edition) in the U.S., or in

Canada, to the Natural Gas and Propane Installation

Code (CSA B149.1 latest edition). The vent system

must be sized and installed for a Category I Fan-

Assisted Appliance.

If chimney height is greater than 25 feet, or

if multiple units are vented into the same vertical

vent, a barometric damper must be installed on each

appliance, such that the flue draft does not exceed

(negative) 0.1 in. w.c.

If using a power venter for any type of Category

I venting, the draft should be set between (negative)

0.01 and 0.05 in. w.c.

2.2.3 Common Venting Systems

Pennant units are Category I fan-assisted when

vented vertically and adhering to all applicable codes.

Pennant units are not allowed to be vented into a

common horizontal vent system, unless a properly

sized vent fan is used, and the common vent system

is properly designed by the vent fan manufacturer or

a qualified engineer. When common venting Pennant

fan-assisted unit with other appliances through

one shared vertical duct called a “common vent”,

special care must be taken by the installer to ensure

safe operation. In the event that the common vent

is blocked, it is possible, especially for fan-assisted

devices, to vent backwards through non-operating

appliances sharing the vent, allowing combustion

products to infiltrate occupied spaces.

If the

appliances are allowed to operate in this condition,

serious injury or death may occur.

WARNING

Operation of appliances with a blocked common

vent may lead to serious injury or death. Safety

devices must be implemented to prevent blocked

common vent operation. If safe operation of all

appliances connected to a common vent cannot

be assured, including prevention of spillage of flue

gasses into living spaces, common venting should

not be applied, and appliances should each be

vented separately.

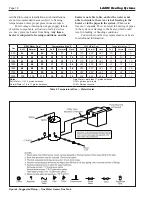

Figure 2. Combustion Air and Vent Through Roof.

Term

Description

Pipe

Single-wall galvanized steel pipe, 24 gauge

minimum (either insulated or non-insulated)

Joint Sealing Permanent duct tape or aluminum tape

Table 4. Required Combustion Air Piping Material.

Summary of Contents for Pennant PNCH

Page 23: ...Low Temperature Pennant Page 23 Figure 12 Ladder Diagram Sizes 500 1000 ...

Page 24: ...LAARS Heating Systems Page 24 Figure 13 Ladder Diagram Sizes 1250 2000 ...

Page 25: ...Low Temperature Pennant Page 25 Figure 14 Wiring Diagram Sizes 500 1000 ...

Page 26: ...LAARS Heating Systems Page 26 Figure 15 Wiring Diagram Sizes 1250 1500 ...

Page 27: ...Low Temperature Pennant Page 27 Figure 16 Wiring Diagram Sizes 1750 2000 ...