Page 14

a bypass plug must be installed in the fuel pump.

The plug is supplied with the oil burner. There is

a decal located on the fuel pump showing where

the bypass plug goes.

If a fuel unit is set up for a two-pipe system, but

is actually connected to a one-pipe system, the

pressure in the fuel pump builds up to over 300

psi when the burner turns on. This will cause the

motor to bind and stop running or ruin the pump

seals, or both,

2.

An oil filter must be installed on the inlet line. A

very small amount of dirt in the oil can plug the

nozzle. A properly sized oil filter is shipped with

the heater (see Fig. 11).

3.

Is there oil in the storage tank?

4.

Are all of the shut-off valves on the oil lines

open?

5.

Are the fuel lines adequately sized according to

the table on page 5?

6.

Are there any leaks in the fuel line? A very small

leak can cause the fuel pump to suck air into the

system, resulting in failure to operate or a

pulsating, noisy fire.

7.

Is the unit properly grounded electrically? This is

extremely important. Use of PVC piping in the

pool filter system prevents grounding through the

piping.

8.

If a time clock is installed, is there power to the

timer? Is the timer motor working? There is

usually a visual motor check opening on the timer

mechanism. Is the switch located below the timer

dial “ON”?

9.

Are there any loose wires or terminals?

10.

Is the pool filter clean, and is the pump operating

properly?

4D. Operating Sequence

When every part of the system is working

properly, the heater will go through the following

sequence:

1.

When the filter pump builds up enough pressure

in the piping, the contacts in the heater pressure

switch close.

2.

The heater thermostat calls for heat completing

the circuit between the two thermostat terminals

on the primary control of the oil burner.

3.

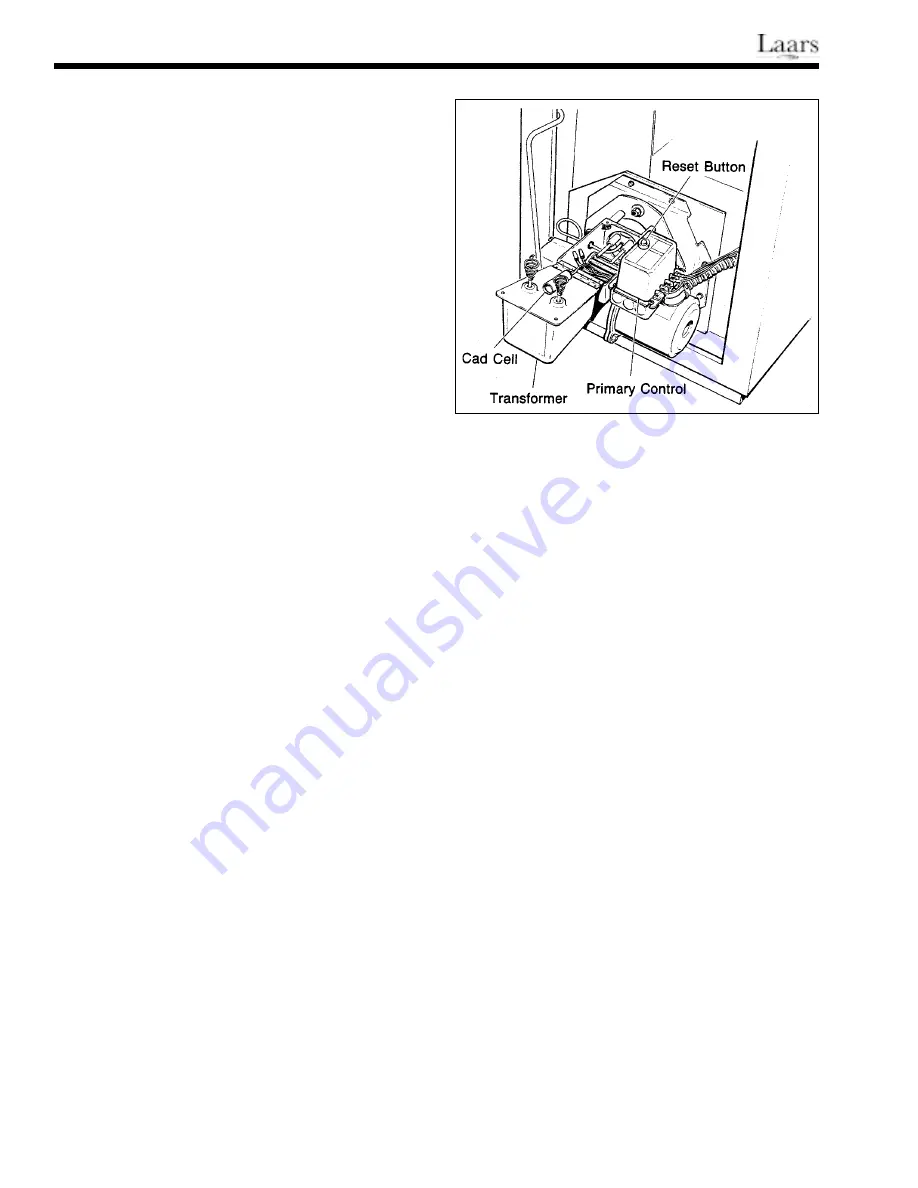

The primary safety control on the oil burner goes

through a self-test sequence. One of the steps in

the sequence is to check out the cadmium cell

flame detector. If the cad cell senses light, the

burner will not fire. If everything checks out, the

burner motor and ignition transformer are

powered.

On 60Hz models, the ignition transformer

operates during the entire burner operation.

4.

If the cad cell does not sense a good flame within

30 seconds the primary control de-energizes the

motor and ignition transformer. This turns off the

heater. It can be manually restarted by pushing

the reset button after waiting about one minute.

5.

During the period when the filter pump is

running, which is set by the time clock, the

thermostat will turn the burner on and off as

required to maintain the water temperature set on

the thermostat.

6.

If a time clock is used, the contacts in the

Fireman switch open about 20 minutes before the

pool filter cycle is completed. This shuts off the

oil burner. The oil burner cannot be restarted

during this period. The filter pump continues to

run for another 20 minutes, transferring any heat

stored in the firebox to the pool.

4E. Troubleshooting

NOTE: These troubleshooting procedures

require connections to electrical terminals and jumper

wires to check operation. To avoid electrical shock,

turn off electric power before servicing line voltage

controls. Never leave a jumper wire in place to fix a

heater. This would bypass safety and operating

controls.

4E-1. Burner will not start (motor and

transformer do not come on)

Figure 20. Cad Cella and Primary Control.