Model DP Oil-Fired Heater

Page 11

SHOULD START THE OIL BURNER.

Check the operation of the burner. Make sure of

the proper air adjustment. Check the flame pattern and

temperature. The air shutter is factory set for 12%

C0

2

, but verify this after installation.

1.

Start the filter pump. Let it run for about five

minutes to free any trapped air.

2.

Set the thermostat well above the pool water

temperature.

3.

Turn the heater switch ON. If the burner motor

does not start right away, reset the manual

overload switches on the motor and primary

control. If the motor runs but the burner fails to

light, it may be necessary to bleed air from the

fuel line. See Step 5.

4.

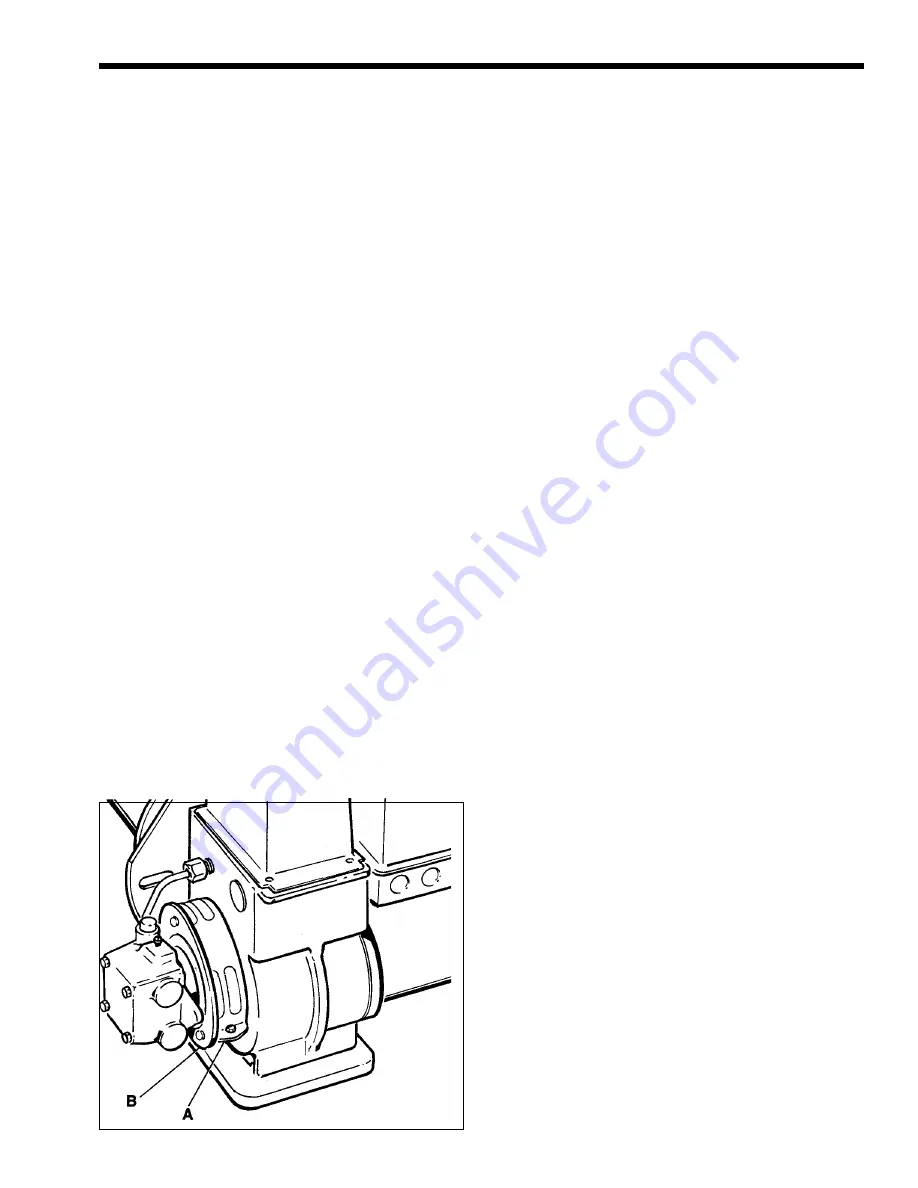

Check the initial air adjustment (see Fig. 17).

Normally, the bulk air band (A) and the end air

shutter (B) should be partially open. It is factory

set for both indoor and outdoor installations, but

check it again after completing the installation by

measuring the C0

2

, It should be 12% C0

2

with

zero smoke. Set a barometric draft control to

give .02" to .03" W.C. draft below the draft

control when the heater is installed indoors.

5.

When the heater is attached to a two-pipe

system, the fuel pump will automatically vent air

out of the fuel lines. If there is a lot of air, the

primary control may shut the burner down before

all the air has been purged. If this happens, wait

2 minutes, then press the reset button on the

primary control. Repeat this procedure until all

the air has been vented and the unit fires properly

(see NOTE below). If a one-pipe system is used,

it must be thoroughly purged of air using the vent

plug on the oil pump.

IMPORTANT: If there is no ignition after three

reset attempts, stop. Check for accumulated oil in the

firebox. Remove all unburned oil with dry rags before

continuing the restart procedure. If there is no oil

accumulated, try three more re-sets. If there is still no

ignition, have a qualified oil service technician bleed

the fuel line and check for ignition problems.

When the heater does fire, oil which is in the

firebox will cause considerable smoke as it burns off.

6.

Set the thermostat to the desired temperature.

Until the pool water reaches a temperature of

approximately 70°F (21°C), there may be

condensate on the heat exchanger. This will stop

after the water reaches the right temperature.

NOTE: The firebox in the heater is made from

the best high temperature material available. Starches

have been added to this material during the molding

process. When the heater is first fired, the starches

oxidize producing noticeable smoke. This will stop

after about an hour of operation.

If the heater is installed in an enclosed area, keep

all doors and windows open during the first two hours

of operation. After a long shutdown, there may be

some smoke-like emissions from the heater when it is

first fired. This condition will only last a few minutes.

3B. Setting the Time Clock

The most economical and trouble-free way of

operating a pool heater and filter system is to include a

time clock in the system for automatic cycling.

Adjust the stops on the time clock to provide a

single filter cycle every 24 hours.

The ON cycle should be at least 12 hours to

allow the filter system to properly clean the pool. Set

the ON cycle at least 4 to 6 hours before the pool is to

be used. During cold spells, the heater may have to be

on longer to maintain the proper pool temperature.

Remove all stops on the time clock during these

periods.

IMPORTANT: Run the heater continuously

during the initial warm-up period by removing all time

clock stops. If the pool temperature is going to be

maintained on standby temperature, operate the filter

pump until the water temperature reaches 70°F (21°C).

If the pool is going to be used for swimming, bring the

water up to swimming temperature before replacing the

Figure 17. Initial Air Adjustment.