About Chisels

KVAL Service Manual

3-32

Changing Chisels on a Machine

To change the chisels, turn off power and air to the machine.

1.

Perform Lockout/Tagout

2.

With the air off, the chisel cylinders can be pulled out of their retracted position to

work on the chisel(s).

3.

Remove covers to access the chisels

Important:

Be alert that all tools in the assembly are sharp and can cause injury.

4.

Using a 7/16” wrench, loosen and remove the bolts retaining the chisel clamps.

Remove the clamp and chisel.

5.

Clean off any particulate that may have accumulated on the clamp and chisel area.

This is especially important for the lower tools, where particulate can get trapped on

the tool surface instead of falling under gravity’s influence.

6.

Place the new chisel in the fixture, add the clamp, and tighten down the bolts back

onto the clamp.

7.

Verify that the chisel does not wobble in the fixture after tightening. Chisels should

be rigid and straight in the assembly.

8.

Push the chisel cylinder back into the machine head.

Clear the machine area and turn back on air and power to the machine.

This machine is a powerful electro-mechanical

motion control system. If servicing this machine, fol-

low the safety guidelines. Failure to do so can result in

damage to equipment and/or serious injury to person-

nel. Shutdown the machine and follow the

“Lock Out

Tag Out procedures.

Caution

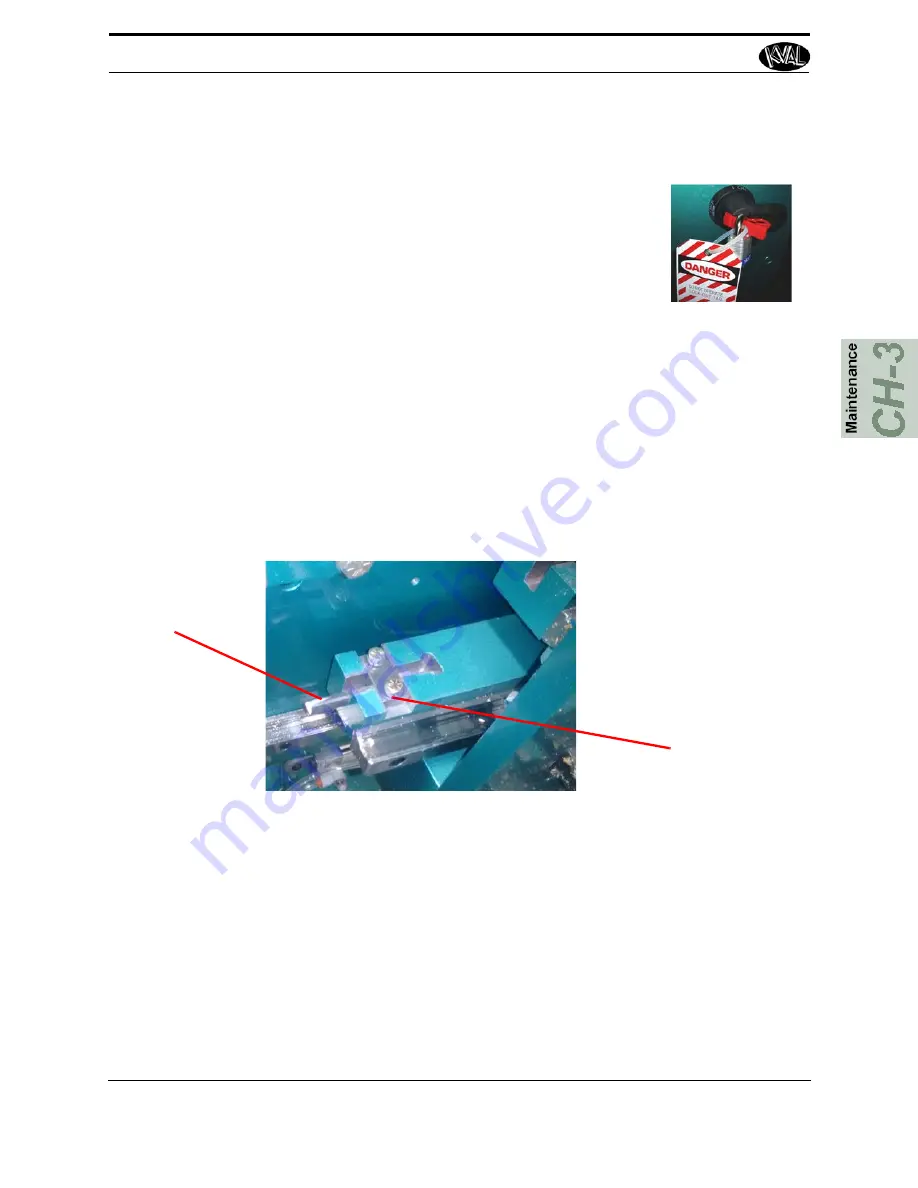

Clamp

Chisel

Summary of Contents for EFX

Page 4: ...KVAL EFX System Service Manual ...

Page 6: ...KVAL EFX System Service Manual ...

Page 11: ...Notes ...

Page 31: ...Safety Sign Off Sheet KVAL Service Manual 1 20 ...

Page 35: ...About Backing up the Data KVAL Service Manual 2 4 ...

Page 75: ...Collet Torque Values KVAL Service Manual 3 40 ...

Page 76: ...Notes ...

Page 103: ......

Page 106: ......

Page 107: ......