How to Enter Calibration Data

4-5

KVAL Operation Manual

How to Enter Calibration Data

Adjustment menus are located in the setup screens. In these menus, you can add negative or posi-

tive adjustments to move a servo to desired positions to compensate (calibrate) for any deviation’s

from the expected cut. The calibration can then be stored.

Below are general instructions to perform a calibration.

1.

Check for deviations between the expected machining and actual machining. Mea-

sure the offset from the expected result. Use this number to enter into the offset box

under the inaccurate parameter.

Note:

Maximum offset is 0.50 inches. If more than 0.50 inches of adjustment is

needed, there is a high probability that another issue may be causing a problem.

If issues can not be resolved, contact the Service Center Inc. (1-800-553-

5825).

6.

Run a test door again to verify the offset correction was successful.

7.

Keep running a test door and adjusting the offset until satisfied with the result

About Restore Points

Restore Points can be created to store a calibration point for recall.

2.

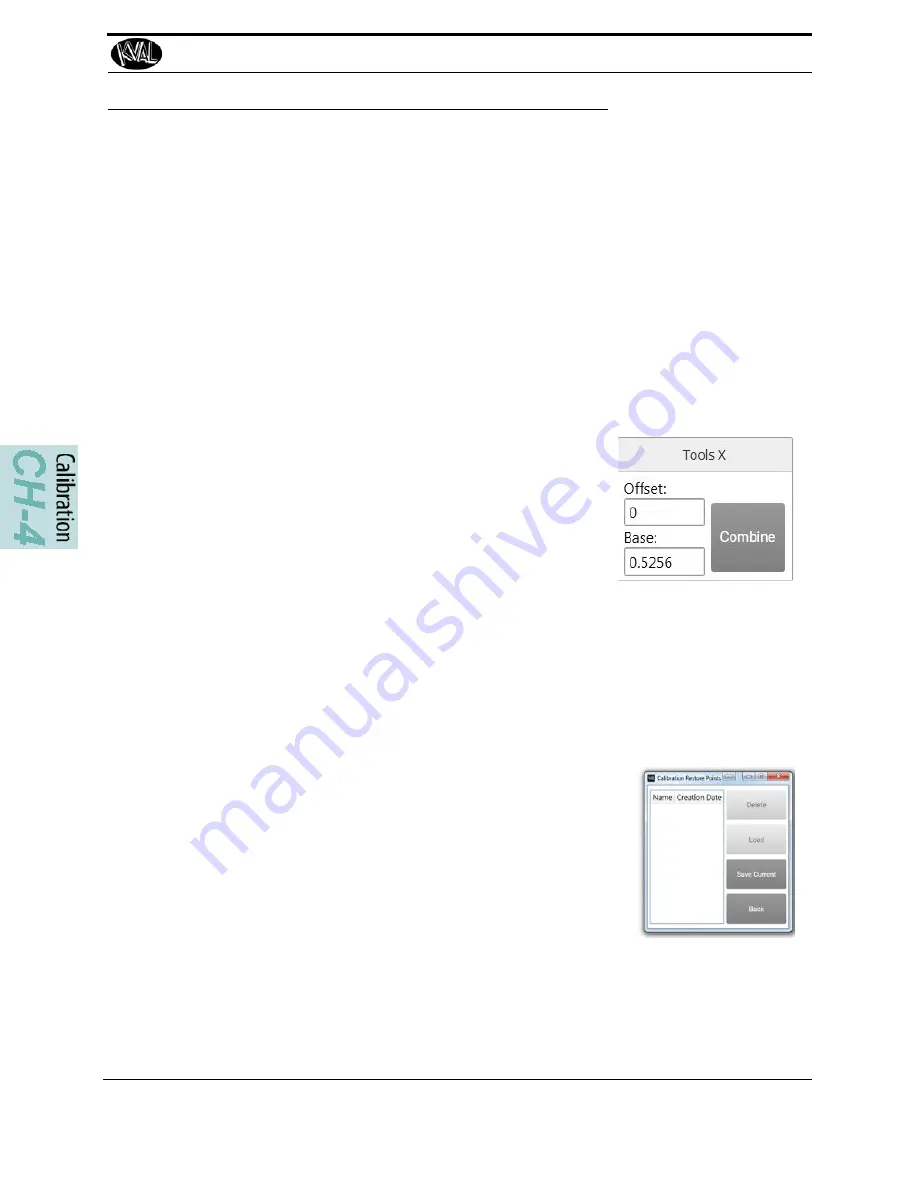

Enter the offset positive or negative number in the white

box below the

Offset

title to adjust the servos in the X,

Y, and Z directions.

3.

The

Base

display box keeps a running total of data

entered to help keep track of the changes.

4.

The

Combine

button merges the offset number to the

base to adjust the servo.

5.

Click the

Save

button to store the calibration.

To create a Restore Point:

1.

Select the

Restore Points

button

2.

Select the

Save Current

button from the pop-up window

save current calibration

3.

Name and enter to save

To Load or Delete a Restore Point:

1.

Select the restore point from the menu

2.

Select the

Load

button to use the calibration. Select the

Load

button to load

3.

Select the

Delete

button to delete the point.

Summary of Contents for Edge-SS

Page 4: ...KVAL Edge SS System Operation Manual ...

Page 6: ...KVAL Edge SS System Operation Manual ...

Page 12: ...KVAL Edge SS Manual Table of Contents ...

Page 49: ...About Revisions 2 16 KVAL Manual ...

Page 84: ...Common Terms 2 51 KVAL Manual FIGURE 2 11 Example of a Validation Report ...

Page 147: ...About the Nodes 5 21 KVAL Operation Manual ...

Page 149: ...Index Kval Edge SS clean up 12 inspect 12 ...

Page 150: ......

Page 151: ......