-17-

LUBRICATION

* PTO transmission shaft (item 8) : Grease the telescopic tubes and universal knuckle

joints daily (2 grease nipples) with Shell Multi-purpose grease NLGI grade 2.

* Depth wheels (item 12) : Greased for life with Shell Multi-purpose grease NLGI grade

2.

* Rotor : Periodically grease (approx. every 20 hours) with Multi-purpose grease NLGI

grade 2, the grease nipple (item 14) situated at the non-drive end of the rotor.

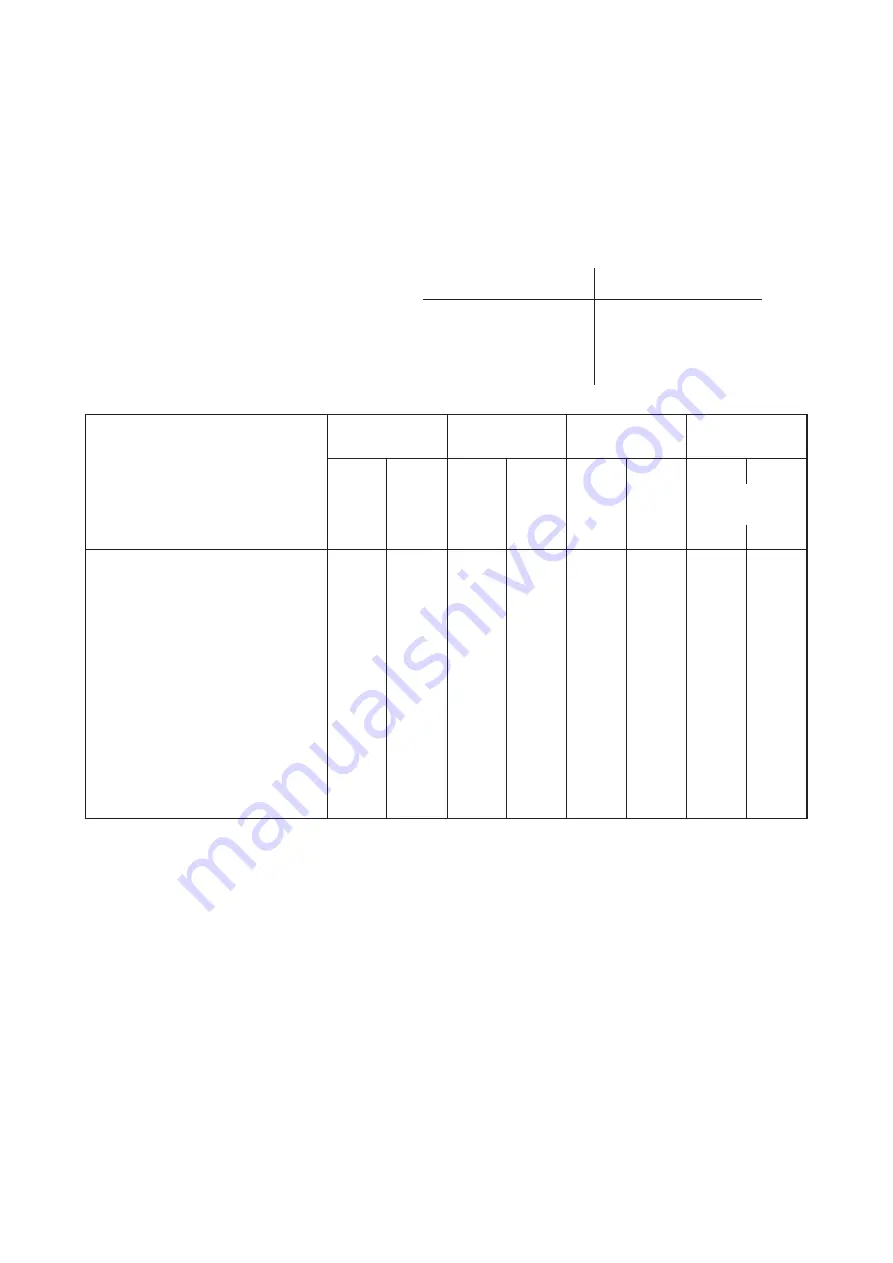

OPERATION

The tilth depends on the type of work to be carried out. The degree of tilth is governed

by combining the following factors :

- 2 or 3 pair formation

- Position of rear shield

- Rotor speed

(rotational frequency)

- Forward speed

- Working depth

FINE TILTH

COARSE TILTH

- Rotor speed

(rotational frequency)

2nd

1st

- Rear shield

Down

Up

- Forward speed

Slow

Fast

- Blade formation

3 pairs

2 pairs

Proposed combinations

Rotor speed

Rear shield

Tractor

Blade

rpm

(min

-1

)

position

speed

formation

Work required

2nd

1st

1,6 to 3

3 to 6

3

2

238

182

Down

Up

km/hr

km/hr

pairs

(1 to 2

(2 to 4

mph)

mph)

Seedbed preparation spring

*

*

*

*

Seedbed preparation autumn

*

*

*

*

*

Turning in green crop

*

*

*

*

Turning in crop residues

*

*

*

*

Turning manure

*

*

*

*

Reclamation of grassland

*

*

*

*

*

Vineyard cultivation

*

*

*

*

Orchard cultivation

*

*

*

*

Weeding

*

*

*

*

Land clearance

*

*

*

*

*

Brushwood clearance

*

*

*

*

*

Turning in stubble

*

*

*

*

*

Market gardening

*

*

*

*

*

Forest maintenance

*

*

*

*

The EL 100 N fitted with cultiplow rotor or with cultitiller rotor is designed for

following types of work :

- Soil cultivation in ploughed land.

- Market gardening.

- Reclamation of grassland.

- Turning in stubble.

- Surface and indepth soil loosening.

Summary of Contents for EL 100 N

Page 1: ...ASSEMBLY OPERATOR S MANUAL EL 100 N POWER TILLER N 95458 A GB 12 1999...

Page 10: ...8...

Page 18: ...16...