-15-

2. CULTIPLOW ROTOR

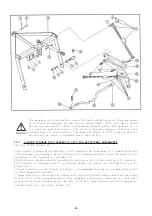

On EL 100N equipped with

cultiplow rotor, blades (L)

must be fitted alternatively

to the left and right-hand

side of the flanges.

- All bolts go on the blade side and the nuts and lock washers on the flange side.

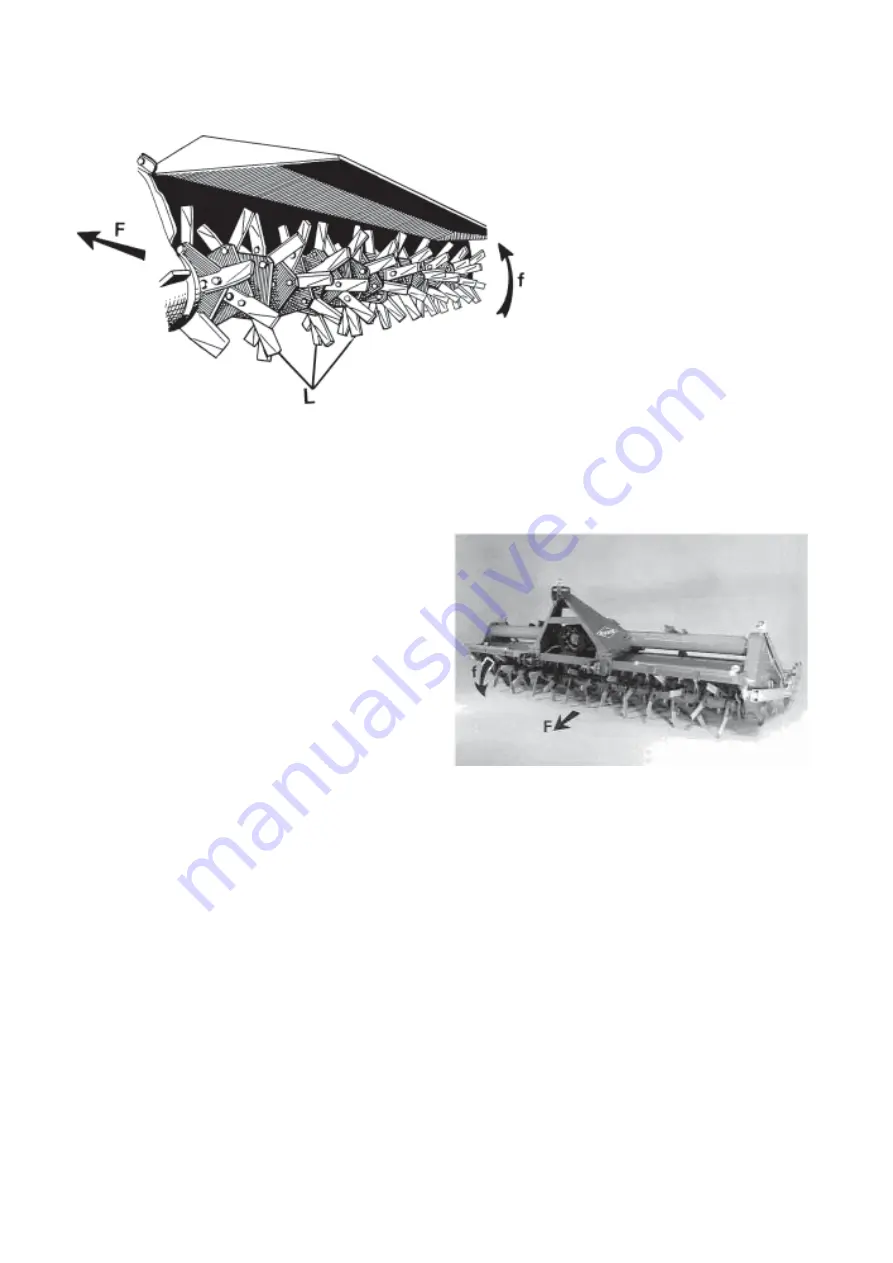

3. CULTITILLER ROTOR

The cultitiller rotor is equipped with

angled blades bolted onto supports

individually welded on the rotor central

tubing. When fitting blades, start on

the left hand side support (i.e. gearbox

side) by facing the blade cutting edge

towards the left-hand side of the

machine (viewed in the forward direction

F).

Next fit the diametrically opposite

blade by facing the cutting edge towards

the right-hand side of the machine. Keep

fitting left-hand and right-hand blades

alternatively, moving towards the right-

hand side support, ensuring that all

cutting edges always follow the direc-

tion of rotation (f).

CAREFULLY TIGHTEN UP ALL BOLTS : - 16 daNm (118 ft/lbs) for the standard rotor with

angled blades

- 22 daNm (162 ft/lbs) for the cultiplow rotor and

for the cultitiller rotor.

When the blades or spades are worn, change the complete set to avoid throwing the

rotor out of balance.

Diagram : clod sizes

This diagram shows theoretically achieved clod sizes with variable parameters such

as number of pair of blades fitted, forward speed and selected rotor speed

(rotational

frequency).

Summary of Contents for EL 100 N

Page 1: ...ASSEMBLY OPERATOR S MANUAL EL 100 N POWER TILLER N 95458 A GB 12 1999...

Page 10: ...8...

Page 18: ...16...