Type

RA-2 HV3

Operating Instructions

DOK-208-GB.doc

No. 0920-..,

0921-...

Radiators or water pipes do not provide sufficient earth contact! During breaks in

operation or when shutting down the equipment as well as prior to dismantling or the

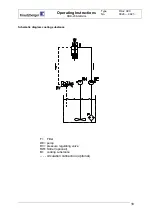

start of repair and maintenance work, you should ensure that the automatic spray gun is

no longer under pressure (close material feed, open control air until material pressure

has dissipated, close control and atomiser air supply)!

During breaks in operation (e.g. work breaks), shut off the air supply! In particular, shut

off the control air! Check whether material escapes! Repair if necessary!

Prior to each repeat startup, check the connections and settings and monitor the

automatic spray gun type RA-2 HV3 for seal tightness (no uncontrolled air and/or

material discharge)!

Adhere to the pressures and temperatures listed under "Technical Data"!

When working at temperatures above 43°C, attach protective devices and post

notification concerning the risk of combustion due to coating substance and/or heated air,

and draw particular attention to risks resulting from leakage or bursting of the spray gun!

Ensure that neither spraying nor air or material discharge can be activated accidentally or

by defects in the unit as long as one or more persons are in the hazard zone. Take steps

to ensure that no alterations can occur or be made to the control and/or atomiser air feed

or the material pressure during setting and maintenance work without the knowledge or

consent of the setup technician!

Check wearing parts at appropriate intervals and replace if necessary!

Only use spare parts and accessories from Krautzberger GmbH! Krautzberger GmbH

does not assume liability for damage if parts from other suppliers are used!

The instructions and notes of EN 1953 "Spraying Equipment for Coating Substances;

Safety Requirements" are to be adhered to, in particular the warning, hazard and safety

notes pertaining to risks and safety requirements and/or measures

Hazards which exceed those normally expected with the use of spraying equipment have

not come to our attention in the handling of the automatic spray gun type RA-2 HV3. If,

however, accidents or hazardous situations occur during practical applications, please notify

us accordingly.

1.

Use for intended purposes

The automatic spray gun type RA-2 HV3 is designed to allow automatic (not manual)

coating of metal, plastic, ceramics, wood and other suitable surfaces. Typical coating

substances are, for example, lacquers, paints, water-soluble lacquer systems, adhesives,

glazes, enamel, release agents etc.

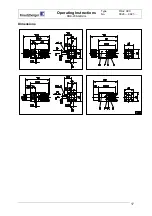

The scope and shape of the jet can be influenced by the choice of nozzle (type and size),

the pressure of the circular or flat jet pair feed and, in certain cases, the material pressure

as well as (to a limited degree) via the limitation of the needle stroke. Depending on the

requirements posed by the material to be processed and/or the shape of the surface to be

3