Type

RA-2 HV3

Operating Instructions

DOK-208-GB.doc

No. 0920-..,

0921-...

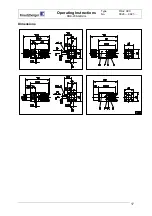

Fully close the flat jet air supply (where flat jet nozzle is present)

Set the circular jet air pressure (do not close completely!)

Set the flat jet air pressure (where flat jet nozzle is present)

Fine tune the settings of circular jet air pressure (and, where applicable, flat jet air

pressure) until the desired spray profile is achieved (see following notes)

Notes

Depending on the type of material feed, the material feed is "opened"

i

by opening the connection valve

i

or by applying pressure to the storage container

i

or by switching the material pump on

i

or by filling the coating substance into the storage container, from where the coating

substance then flows into the automatic spray gun type RA-2 HV3 under its intrinsic

hydrostatic pressure.

If material feed is effected under intrinsic hydrostatic pressure, the material pressure

cannot be regulated.

The optimum needle opening is 8 revolutions (from the opening point). In order to obtain

reproducible settings, the opening point should be monitored after each maintenance

routine and adjusted if necessary,

As the settings of circular and flat jet air pressure as well as material pressure affect

each other, the spray profile has to be set in several steps. It is advisable to set the spray

profile by only varying the circular and flat jet air pressure. The material feed should only

be altered if the desired spray profile cannot be achieved as described above. The

material volume is altered by varying the material pressure and/or the nozzle size.

A limited degree of fine adjustment (for example, to coordinate several automatic spray

guns in a system) can be effected via the adjusting nut (36) - where present.

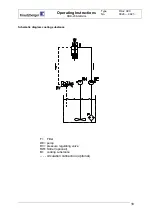

Setting the opening point of the needle

Close the air supply

Close the adjusting nut (36) in a clockwise direction

One revolution of the needle stroke adjuster changes the needle path by 1 mm and

corresponds to 18 locking positions.

Open material feed

Open control air supply; no material should be discharged.

Close the control air, open the adjusting nut by locking position, open the control air,

check whether material is discharged. If this is not the case, repeat these steps until

the opening point is reached and material begins to be discharged.

Note

Rinse the automatic spray gun type RA-2 HV3 through with detergent before first-time use!

7