Type

RA-2 HV3

Operating Instructions

DOK-208-GB.doc

No. 0920-..,

0921-...

19

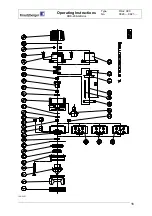

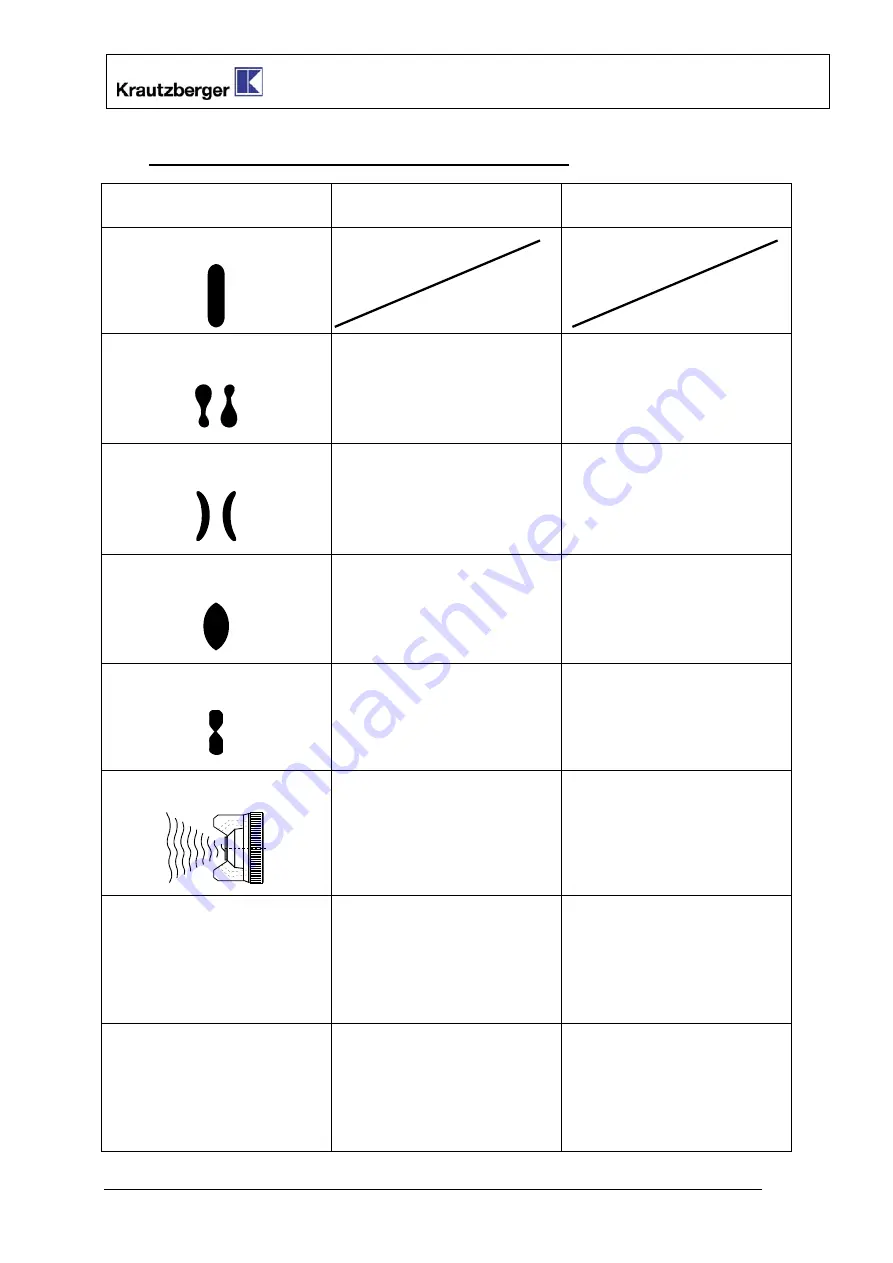

14. Operating malfunctions and spray profile defects

Defect

Cause Remedy

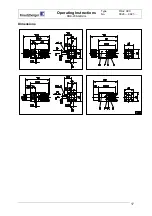

Normal spray profile

Excessive spray profile toward

the top and bottom

Soiled air nozzle

Soiled material nozzle

Clean nozzles

Spray profile veers markedly to

left or right

Soiled air nozzle

Soiled material nozzle

Clean nozzles

Heavy application in the centre

of the spray profile

Two much material

Excessively thick material

Reduce material feed

Dilute material

Split spray profile

Insufficient material

Flat jet air pressure too high

Increase material feed

Reduce flat jet air pressure

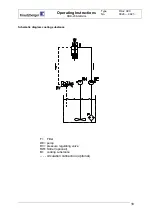

Surging or halting material jet

Insufficient material in pressure

vessel

Blocked material path

Loose or damaged material

nozzle

Worn needle packing

Refill pressure vessel

Clean

Tighten or renew

Replace

Material leakage at packing

screw

Needle packing defective

Replace needle packing

Material nozzle drips

Worn of damaged needle

Soiled or damaged material

nozzle

Replace needle

Clean or replace material nozzle