Type

RA-2 HV3

Operating Instructions

DOK-208-GB.doc

No. 0920-..,

0921-...

Caution

When setting the spray profile, take steps to ensure that no changes can occur or be made

to the settings (setting parameters) without the knowledge of the set-up technician.

The automatic spray gun type RA-2 HV3 is now ready for operation.

5.

Operation of the automatic spray gun type RA-2 HV3 / Correct preliminary air

control

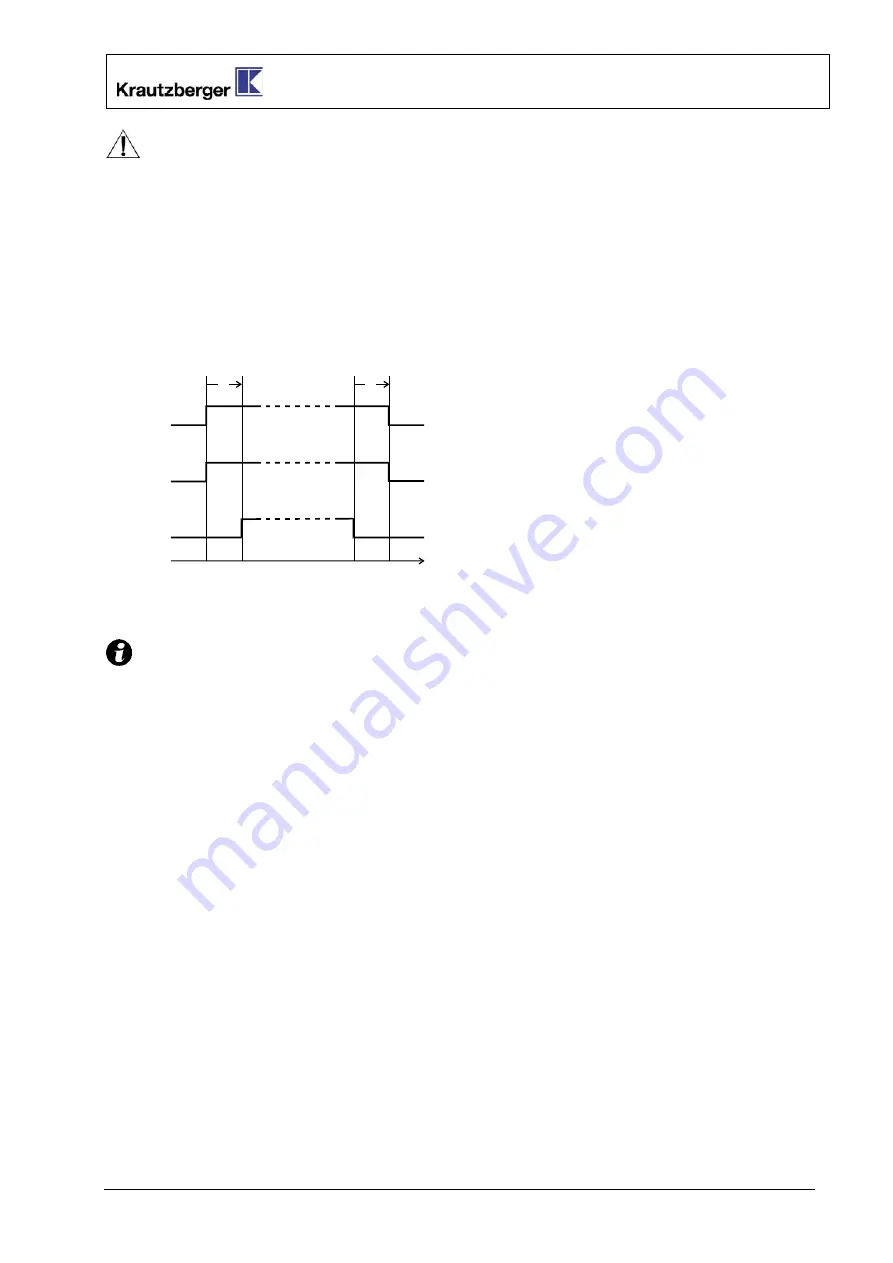

F

=

flat jet air supply

t

F

p

0

R

p

0

St

p

0

t

1

t

2

t

3

R

=

circular jet air supply

St

=

control air (material feed)

p

=

air supply open

O

=

air supply closed

t = time

t1

=

time until atomiser air supply is stable

t2 = automatic spray gun in operation

t3 = time until nozzle is blown clean

Notes

Always adhere to the preliminary air control for (F) and (R) in line with the diagram.

Otherwise

i

material may escape in non-atomised form from the material nozzle at the start of the

spraying process

i

and the nozzles may become soiled or blocked at the end of the spraying process.

Excessive air pressure not only leads to unnecessarily high air consumption but also

generates heavy misting of the coating substance.

Insufficient air pressure results in an unsatisfactory spray profile.

Do not completely close the circular jet air control during operation

Select a low material pressure wherever possible!

7. Changing

parts

Material needle

Unscrew the entire closing piece (31 to 36, where present)

Remove the spring (30)

Pull out parts (38 to 42)

Remove the jam nut (42) from the material needle (39 or 40)

Unscrew the material needle (39 or 40) from the piston (41)

Air gasket (material needle)

Unscrew the entire closing piece (31 to 36, where present)

Remove the spring (30)

8