39

Connection with PC 1

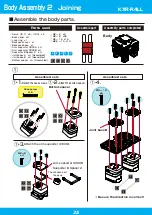

1.

Set the Dual USB adapter HS switch to Serial mode, connect the Black-and-White Extension

Cable, and then plug it into theUSB port of your personal computer.When connected to the USB

port in ICS mode, the Dual USB Adapter HS

LED lights Green.

2.

When connected to the Windows PC for the

first time, the “Add New Hardware Wizard” will

automatically run. Complete the setup following

the KO Driver Installation Manual in the USB

folder in the included CD-ROM.

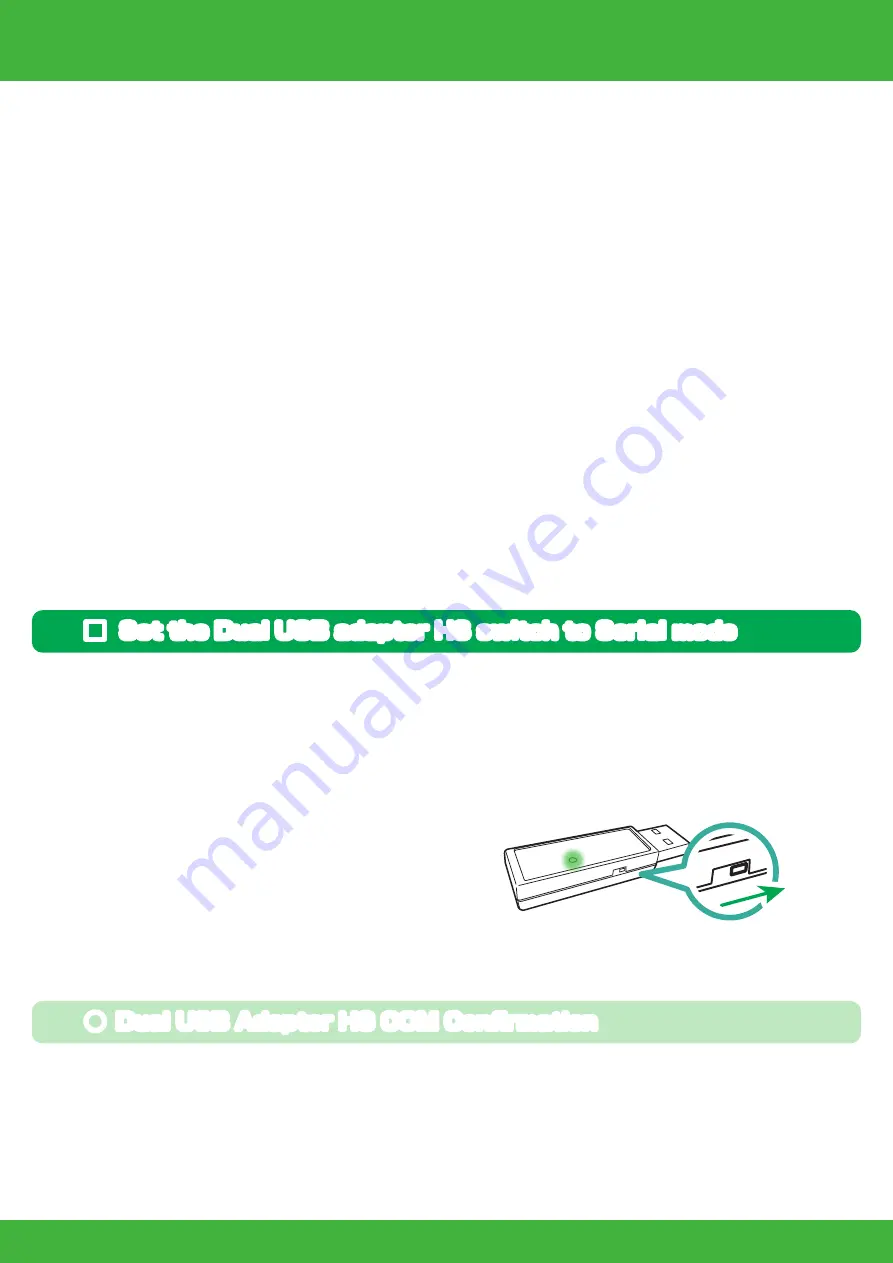

■ Set the Dual USB adapter HS switch to Serial mode

When the Dual USB Adapter HS driver installation is completed, confirm the “COM Port

Number” .This number is important when using the software, so please write it down. The method of

confirming the COM number is included in the KO Driver Installation Manual in the USB folder in the

included CD-ROM. Point Operation Tips Caution for Breakage Confirmation Required.

● Dual USB Adapter HS COM Confirmation

KO Driver is driver software that enables Windows OS to recognize Kondo Kagaku s USB adaptor.

This allows the servos and robot to communicate with the PC via a USB connection.

In the following, adjustments are made to the robot using a computer. When all the processes are

completed, the robot will begin to walk. Conduct the processes by following the procedures below.

▼ Process procedures

Connecting with PC

■ Set the Dual USB adapter HS switch to Serial mode

Connect the Dual USB adaptor HS to the PC

■ Install the HTH4 (HeartToHeart4) motion creation software

Connect the robot to the PC

■ Turn on the robot

Run motion

■ Adjust the trim

Adjust the posture for bilateral symmetry with the robot in the upright position.

■ Run the sample motion

Enable the low voltage motion setting to prevent over discharge, and run the motion.

Serial mode

LED:GREEN