19

UAB KOMFOVENT we reserve the right to make changes without prior notice

RHP PRO_22-01

3. MECHANICAL INSTALLATION

3.1. Requirements for Mounting Location and Installation Base

RHP PRO air handling units are designed for ventilation of medium or large commercial or industrial premises (e.g., stores,

offices, hotels, etc.) where standard air temperature and humidity is maintained. These units are not intended for transport-

ing solid particles within air flows. Standard equipment air handling units are intended for indoor installation; and with ad-

ditional accessories, these units may be mounted outdoors. Air handling units are designed for ambient temperatures from

-30°C to +40°C.

•

RHP PRO units are not intended for operation in areas with potentially explosive atmospheres.

Air handling units are not designed for ventilation and dehumidification of wet areas (pools,

saunas, car washes, etc.).

•

If the AHU is installed in a room with high humidity level, condensate may form on the walls of

the unit at low outdoor temperatures.

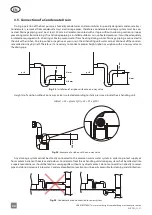

An air handling unit must be mounted on a relatively large and sturdy base, based on the weight of the unit and in ac-

cordance with building regulations. Base must be made of reinforced concrete or metal structures. If the unit is not equipped

with adjustable height feet, it must be installed on a flat base. Vibration dampening gaskets must be fitted between the unit

and installation base. When the unit is not equipped with an installation frame or adjustable height feet, it should be fixed

to the base with metal angle-pieces and rubber vibration dampening gaskets. When installed outdoors, air handling units

must also be attached to the base. During installation, unit sections must be levelled in respect to the horizon: deviations

shall not exceed 0.3 mm for 1 m in the longitudinal direction and 0.5 mm for 1 m in the transverse direction.

L1

L2

L

B

42 - 92

125

60

37,5

L1

L2

200

L

70

70

70

70

70

70

70

2,5

125

2,5

A

A

C

C

B

50

Ø 65

Fig. 15.

Installation frame with adjustable feet