PRODUCT INFORMATION

When requesting service or ordering replacement parts, inform your Komatsu distributor of the following items.

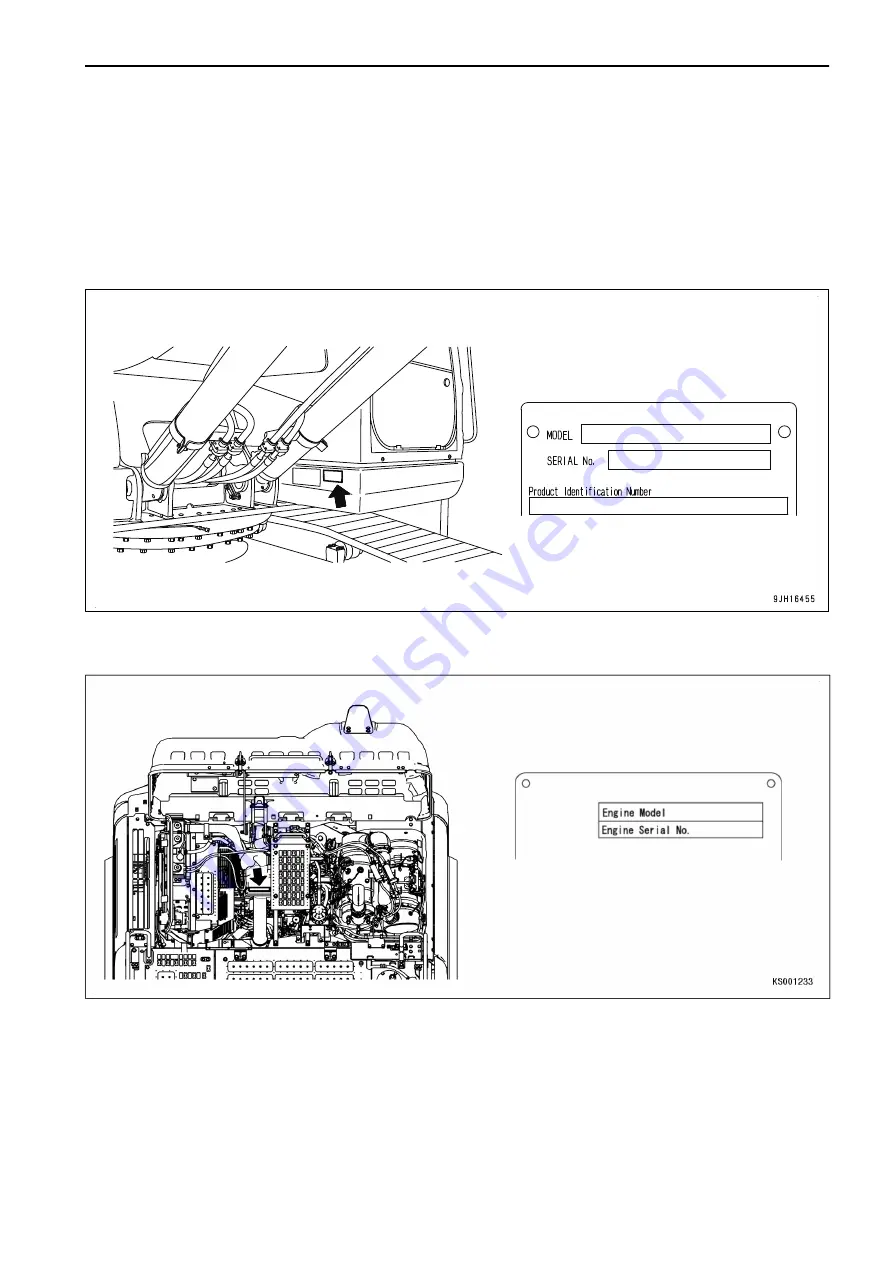

LOCATION OF PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERI-

AL NO. PLATE

It is located on the right bottom of the operator's cab.

The design of the nameplate differs according to the district.

LOCATION OF ENGINE NUMBER PLATE

It is located on top of the engine cylinder head cover.

FOREWORD

PRODUCT INFORMATION

1-11

Summary of Contents for PC360LC-11

Page 2: ......

Page 22: ......

Page 76: ......

Page 344: ......

Page 425: ...SPECIFICATIONS 5 1 ...

Page 429: ...PC360NLC 11 SPECIFICATIONS SPECIFICATIONS 5 5 ...

Page 430: ......

Page 450: ...PC360LC 11 2 Piece Boom PC360NLC 11 2 Piece Boom 2 PIECE BOOM ATTACHMENTS AND OPTIONS 6 20 ...

Page 457: ...ATTACHMENTS AND OPTIONS 17M LONG REACH BOOM AND ARM 6 27 ...

Page 465: ...ATTACHMENTS AND OPTIONS SUPER LONG FRONT BOOM AND ARM 6 35 ...

Page 499: ...REPLACEMENT PARTS 7 1 ...

Page 515: ......