MAINTENANCE PLAN

166

4.7.8 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION

(Only for machines in which the synthetic biodegradable oil type

HEES is used)

4.7.9 MAINTENANCE EVERY 500 HOURS OF OPERATION

4.7.9.a

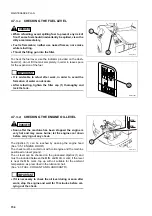

CHANGING THE ENGINE OIL FILTER

The following maintenance operation must be carried out after the first 500 hours of operation, together with the

maintenance operations to be carried out “EVERY 500 HOURS”.

•

HYDRAULIC OIL CHANGE AND SUCTION FILTER CLEANING

For further details on the various maintenance operations, see section “EVERY 2000 HOURS”.

These operations must be carried out together with those to be carried out every 100 and 250 HOURS.

DANGER

•

Soon after the machine has been stopped the engine oil is very hot and may cause burns; let the en-

gine cool down until it reaches a temperature of 40÷45°C before draining the oil.

•

The oil that may be spilled during the change makes the ground slippery, therefore, use anti-slip shoes

and immediately remove any trace of oil from the floor.

•

Oils, filters, the coolant and the battery are considered special waste and must be collected and dis-

posed of according to the anti-pollution regulations in force.

This operation must be carried out every two oil changes.

Proceed as follows:

1 - Drain the engine oil (See “4.7.7.e CHANGING THE ENGINE

OIL”).

2 - Unscrew the used filter (1) with the special spanner provided

and throw it away.

3 - Clean the contact surface between the seal and the filter sup-

port.

4 - Lubricate the seal of the new filter and screw thoroughly.

5 - Give another half turn by hand.

6 - Fill the engine with new oil and complete the operations as

described at point “4.7.7.e CHANGING THE ENGINE OIL”).

Start the engine, make sure that there are no leakages and that

the oil pressure warning light goes out.

IMPORTANT

☞

•

Do not use the spanner to lock the filter, since it may be

damaged and cause oil leakages.

RWA06260

1

Summary of Contents for PC12R-8

Page 2: ......

Page 12: ...10...

Page 20: ...18...

Page 21: ...SAFETY AND ACCIDENT PREVENTION...

Page 23: ...SAFETY NOISE AND VIBRATION PLATES 21 RWA05440...

Page 27: ...SAFETY NOISE AND VIBRATION PLATES 25 EMERGENCY EXIT LIFTING POINT RWA00190 RWA04920...

Page 55: ...THE MACHINE AND ITS OPERATIONS...

Page 88: ...86...

Page 120: ...118...

Page 121: ...MAINTENANCE...

Page 177: ...TECHNICAL SPECIFICATIONS...

Page 198: ...196...

Page 199: ...AUTHORISED OPTIONAL EQUIPMENT...