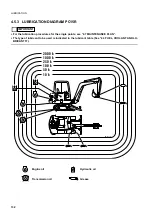

MAINTENANCE PLAN

138

4.7

MAINTENANCE PLAN

4.7.1 WHEN REQUIRED

4.7.2 MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION

HAMMER (BREAKER)

4.7.3 CHECKS BEFORE STARTING

4.7.4 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION

(Only for machines in which the synthetic biodegradable oil type

HEES is used)

N.

PART

OPERATION

PAGE

a

Cooling circuit

Wash

141

b

Fuel tank

Drain the condensate

142

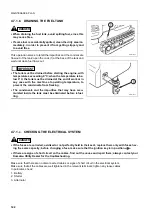

c

Electrical system

Check

142

d

Steel tracks

Check and adjust the tension

143

e

Rubber tracks

Check

145

f

Rubber tracks

Check and adjust the tension

147

g

Rubber tracks

Change

149

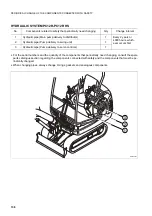

h

Articulation points

Lubricate

151

N.

PART

OPERATION

PAGE

a

Hydraulic oil filter

Change the cartridge

152

b

Hydraulic oil tank

Change the oil

152

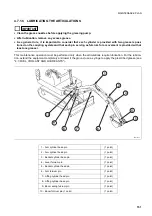

N.

PART

OPERATION

PAGE

a

Various checks

—

153

b

Coolant

Check and top up

153

c

Fuel tank

Check and top up

154

d

Engine oil pan

Check and top up

154

e

Hydraulic oil tank

Check and top up

155

N.

PART

OPERATION

PAGE

a

Hydraulic oil drain filter

(Only for machines with synthetic biodegrad-

able oil)

Change

164

Summary of Contents for PC12R-8

Page 2: ......

Page 12: ...10...

Page 20: ...18...

Page 21: ...SAFETY AND ACCIDENT PREVENTION...

Page 23: ...SAFETY NOISE AND VIBRATION PLATES 21 RWA05440...

Page 27: ...SAFETY NOISE AND VIBRATION PLATES 25 EMERGENCY EXIT LIFTING POINT RWA00190 RWA04920...

Page 55: ...THE MACHINE AND ITS OPERATIONS...

Page 88: ...86...

Page 120: ...118...

Page 121: ...MAINTENANCE...

Page 177: ...TECHNICAL SPECIFICATIONS...

Page 198: ...196...

Page 199: ...AUTHORISED OPTIONAL EQUIPMENT...