MAINTENANCE PLAN

140

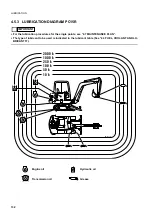

4.7.9 MAINTENANCE EVERY 500 HOURS OF OPERATION

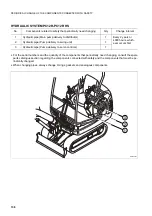

4.7.10 MAINTENANCE EVERY 1000 HOURS OF OPERATION

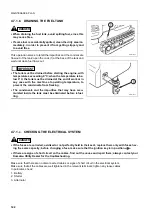

4.7.11 MAINTENANCE EVERY 2000 HOURS OF OPERATION

N.

PART

OPERATION

PAGE

a

Engine oil filter

Change

166

b

Fuel filter

Change

167

c

Fuel pump precleaner

Change

168

d

Air cleaner

Change the cartridge

169

e

Radiators

Clean the outside

169

f

Hydraulic oil tank

(Only for machines with synthetic biodegrad-

able oil)

Drain condensate

170

N.

PART

OPERATION

PAGE

a

Travel reduction gears

Change the oil

171

N.

PART

OPERATION

PAGE

a

Hydraulic oil and suction filter

Change the oil and clean the filter

172

b

Coolant

Change

174

c

Engine valves

Check the clearance

174

d

Alternator and starter

Check

174

Summary of Contents for PC12R-8

Page 2: ......

Page 12: ...10...

Page 20: ...18...

Page 21: ...SAFETY AND ACCIDENT PREVENTION...

Page 23: ...SAFETY NOISE AND VIBRATION PLATES 21 RWA05440...

Page 27: ...SAFETY NOISE AND VIBRATION PLATES 25 EMERGENCY EXIT LIFTING POINT RWA00190 RWA04920...

Page 55: ...THE MACHINE AND ITS OPERATIONS...

Page 88: ...86...

Page 120: ...118...

Page 121: ...MAINTENANCE...

Page 177: ...TECHNICAL SPECIFICATIONS...

Page 198: ...196...

Page 199: ...AUTHORISED OPTIONAL EQUIPMENT...