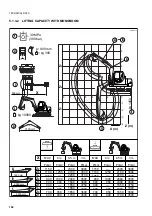

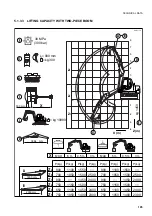

CLAMSHELL BUCKET

208

6.3.2 INSTALLING THE CLAMSHELL BUCKET

DANGER

•

The machine must be parked on a level surface, with the equipment lowered to the ground.

•

When the coupling pins are removed or installed, chips may come off; always use gloves, goggles and

helmet.

•

The change of the equipment must be carried out by two persons, who must decide together the words

and signals to use during operations.

•

Do not use your fingers to center the holes, since they may be injured or even cut.

•

Before carrying out any operation on the hydraulic circuit, eliminate any residual pressure from the

equipment circuits (by shifting the controls more than once) and from the tank (by slowly loosening the

filling cap).

•

Clean immediately any area dirty with oil.

For the installation of the clamshell bucket, proceed as follows:

1 - Remove the standard bucket (see “3.12.5 CHANGING THE BUCKET”).

2 - Withdraw the bucket control piston completely.

3 - Connect the clamshell bucket to the arm.

4 - Stop the machine and move the controls in all directions to release the residual pressures.

5 - Turn the ignition key to position «I» and press the bucket swing control button to release the residual pressure

of the clamshell bucket delivery pipes.

6 - Turn the ignition key to position «O» and remove it.

7 - Mechanically lock the standard bucket push lever, in such a way as to stop the piston at the end of its stroke.

8 - Rotate the tap lever (1) clockwise, until reaching the end of

stroke.

RWAA1470

1

RWAA1450

2

4

Summary of Contents for PC110R-1

Page 2: ......

Page 19: ...17 SAFETY AND ACCIDENT PREVENTION...

Page 51: ...49 THE MACHINE AND ITS OPERATIONS...

Page 126: ...124 PAGE INTENTIONALLY LEFT BLANK...

Page 127: ...125 MAINTENANCE...

Page 190: ...188 PAGE INTENTIONALLY LEFT BLANK...

Page 191: ...189 TECHNICAL SPECIFICATIONS...

Page 198: ...196 PAGE INTENTIONALLY LEFT BLANK...

Page 199: ...197 AUTHORISED OPTIONAL EQUIPMENT...