Page 6

ATTENTION

: If torque isn’t reached by the maximum time, the screwdriver will stop. “

Over maximum

time

” will be displayed on the status bar and the red led will light up. You will hear two beep soun

ds, too.

12) Pre-Rev.: pre-reverse. You can unscrew before tightening. This time can be set from OFF to

20.0 sec.

N.B.

The speed and torque will be the same as those for the Auto Reverse.

13) Auto rev.

–

Auto reverse:

This option will automatically start a reverse after a torque reached signal.

You can set time from 0.1 to 20.0 sec.

To disable the function press

until you get to OFF.

ATTENTION: During the reverse, it is necessary to keep the lever or the start signal pressed as long as it

doesn’t stop. “

Correct screw

” will be displayed on the status bar and a green led will light up. You will

hear one b

eep sound, too. In case the lever is released before the end of the reverse, “

unfinished screw

”

will be displayed and a red led will light up. You will hear two beep sounds, too.

14) Rev spd - Reverse speed:

You can select any reverse speed value of the screwdriver between the

maximum and the minimum specific speed of every single screwdriver (see table with technical data).

15) Rev torque

–

Reverse torque:

You can select the desired reverse torque as a percentage of the

torque range of the selected screwdriver (see point 2). If the torque is set on MAX, the reverse torque is

about 20% higher than the possible maximum torque, so that it is always possible to unscrew a tightened

screw (we suggest leaving this function on in normal use). If the setting is from MIN to 99% the reverse

torque with the same percentage will be equal to the settings of the screwing phase.

ATTENTION:

If you’re using open

-end wrenches, the reverse torque has to be set to MIN value in

order to bring the wrench back to the correct position.

16) PV torque:

Period of time in which the screwdriver works at maximum torque before switching to

the torque that has been set by the user. You can set time from 0.1 to 10.0 sec.

To disable the function press

until you get to OFF.

This function overlaps other time settings (brake time, ramp time, minimum time, maximum time) from the

motor start on.

ATTENTION: This function is useful for applications where the prevailing torque is higher than the final

torque (for example trilobal screws or locknuts).

Please use this function with utmost attention because an incorrect use can damage both the assembly

and the screwdriver.

Torques reached during the max torque time won’t activate the torque signal. “

Error pvt time

” will be

displayed and the red led will light up. You will hear two beep sounds, too.

17) Rotation:

You can choose between right tightening (standard screws) or left tightening (left threaded

screws). All the other functions will adapt to the selected direction of rotation.

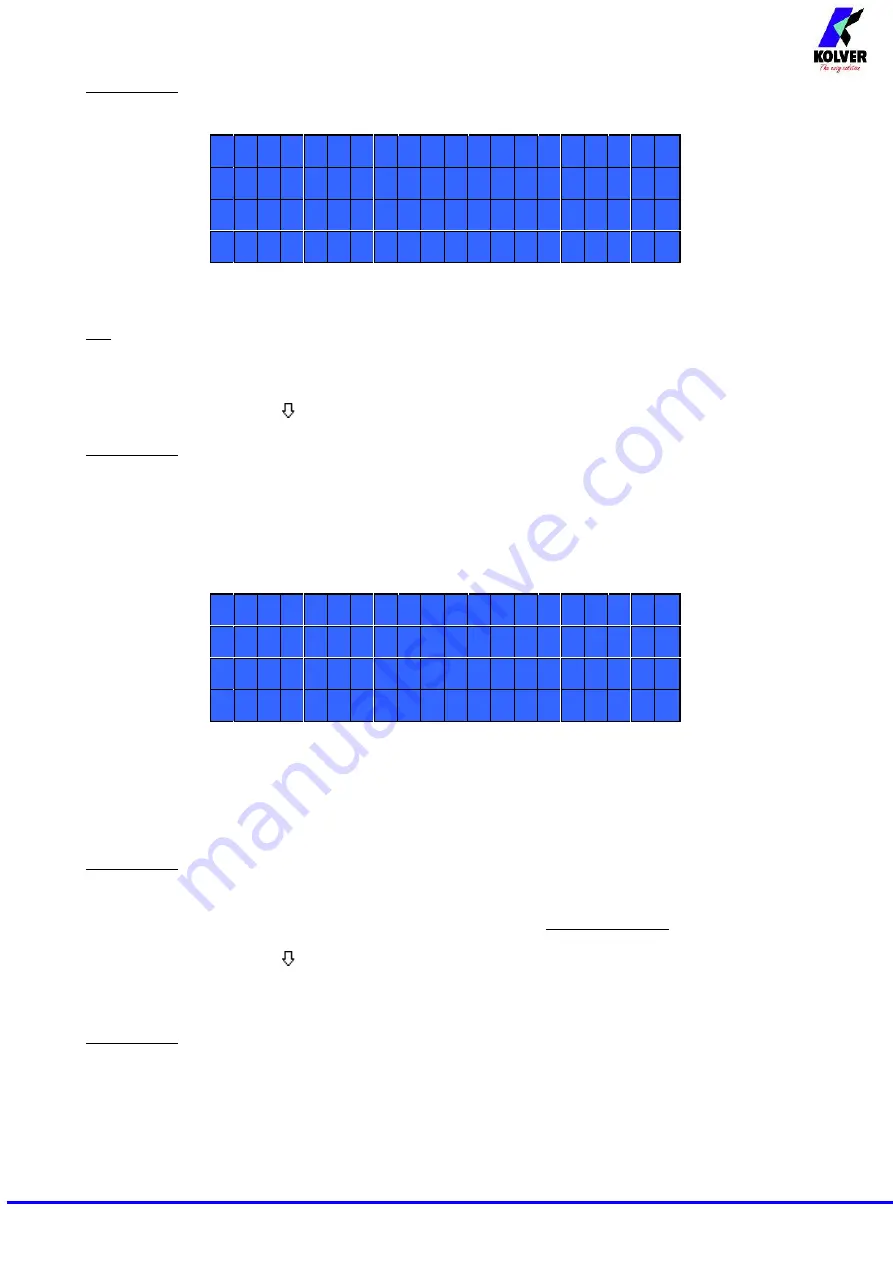

- - - - - M E N U - - P R : 1 - - - - -

1 2 ) P r e

R e v :

o f f

1 3 ) A u t o

R e v :

2 0 . 0 s

1 4 ) R e v

s p d :

- - - - - M E N U - - P R : 1 - - - - -

1 5 ) R e v

t o r q u e :

M A X

1 6 ) P V

t o r q u e :

o f f

1 7 ) R o t a t i o n :

r i g h t

Summary of Contents for EDU 2AE/TOP/NT

Page 17: ...Page 17 I O CONNECTIONS...