- 42 -

= 8.8

8.8

= R10 = 10.9

R10

= R12 = 12.9

R12

kgm

0,52

1,01

1,73

2,84

4,25

5,45

7,54

12,80

19,40

29,50

37,00

51,50

62,40

80,00

Nm

5,1

9,9

17

27,8

41,6

53,4

73,8

125

190

289

362

504

611

784

kgm

0,62

1,22

2,08

3,40

5,10

6,55

9,05

15,30

23,30

35,40

44,40

61,80

74,90

96,00

Nm

6

11,9

20,4

33

50

64.2

88.7

150

228

347

435

605

734

940

R ≥ 800 N/mm

2

R ≥ 1000 N/mm

2

R ≥ 1200 N/mm

2

Nm

3,6

7

12

19,8

29,6

38

52,5

89

135

205

257

358

435

557

kgm

0,37

0,72

1,23

2,02

3,02

3,88

5,36

9,09

13,80

21,00

26,30

36,60

44,40

56,90

4 x 0,70

5 x 0,80

6 x 1,00

7 x 1,00

8 x 1,25

9 x 1,25

10 x 1,50

13 x 1,75

14 x 2,00

16 x 2,00

18 x 2,50

20 x 2,50

22 x 2,50

24 x 3,00

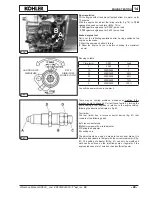

XVI

kgm

2,7 ÷ 2,8

4,6 ÷ 5,6

2 ÷ 2,5

0,8 ÷ 0,9

2

4

18 ÷ 20

3,8 ÷ 3,9

(Nm)

26,5 ÷ 27,5

45 ÷ 55

19,6 ÷ 24,5

7,8 ÷ 8,8

19,6

39,2

176,5 ÷ 196,1

37,3 ÷ 38,2

16

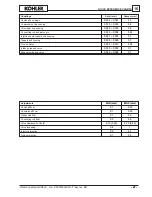

Quick reference charts

Standard screw tightening torques

Denomination

Diameter x pitch mm

Tightening torques

Timing system cover

Injector ring nut

Injection tube unions

Injector bracket

Injection pump bracket

Head

Flywheel

Connecting rod

Workshop Manual KD500 _ cod. ED0053029390 -

1° ed

_rev.

00