Operating manual

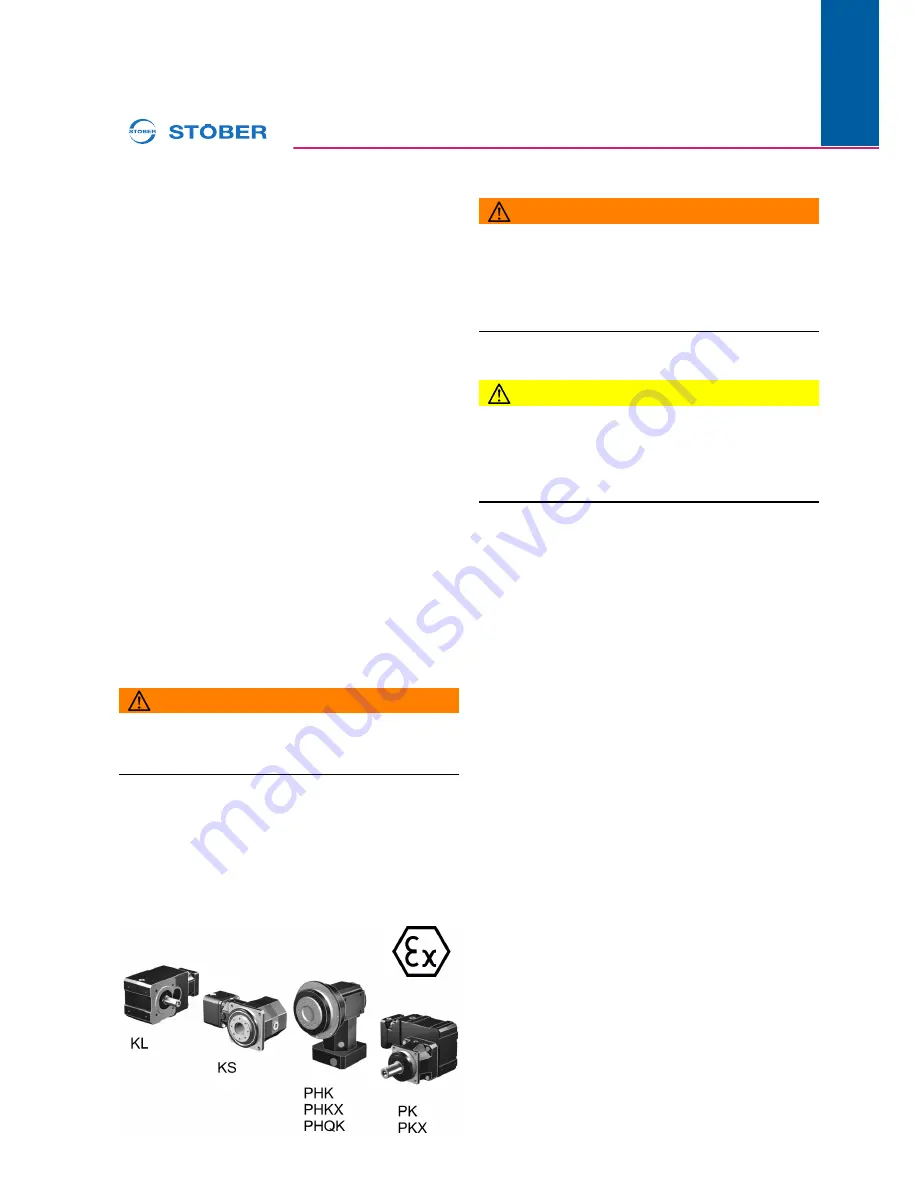

Explosion-protected right angle servo gear units KL/KS/PHK/PHKX/PHQK/PK/PKX

1

01/2019

WE KEEP THINGS MOVING

ID 443005_en.01

en

www.stober.com

These operating instructions contain information about the

transport, assembly, commissioning and service of gear units

from STOBER. Observe the applicable documents of

attached motors and additional drive components.

1

Operation in accordance with its

intended use

Explosion-protected gear units from STOBER meet the

requirements of the ATEX Directive 2014/34/EU and comply

with the following standards:

•

EN 1127-1:2011-07

•

EN ISO 80079-36:2016-04

•

EN ISO 80079-37:2016-04

The gear units are intended for installation in commercial

machines and systems. Intended use includes:

•

Use of the gear unit exclusively for the application that it

was designed for.

•

No modifications to the gear unit by the customer.

•

Use of the gear unit only in the zone subject to explosion

hazard that corresponds to the identification on the ATEX

nameplate.

•

Use of the gear unit in the surrounding temperature range

Ta that is specified on the ATEX nameplate.

•

The maximum thickness of the dust deposit on the gear

unit may not be more than 5 mm according to EN 50281-

2-1.

•

No overload of the gear unit with regard to the maximum

permitted speeds and torques that are specified in the

order confirmation.

•

Compliance with the inspection and maintenance

intervals.

•

Observe these operation instructions.

WARNING!

Unintended use of the gear unit can lead to explosions

that can cause serious injuries or even death.

Only use the gear unit as intended!

2

Safety information

WARNING!

Failure to comply with these operating instructions can

cause ignition sources when using the gear unit in areas

subject to explosion hazard and lead to explosions that

can cause serious injuries or even death.

Comply with the instructions in these operating

instructions!

Also follow the applicable national, local and system-specific

requirements.

CAUTION!

Burns!

The surface temperature of the gear unit can significantly

exceed 65° C in operation!

Allow the gear unit to cool down sufficiently before

touching it or wear protective gloves.

2.1 Ignition hazard and protective

measures

The following is an overview of ignition hazards that can arise

when operating the gear unit and protective measures that

are described in these operating instructions.

Ignition hazard: hot surfaces

Possible causes: increased friction due to improper

assembly, wear, overload or leaks.

Protective measures:

•

Compliance with the maximum permitted torques and

speeds

•

Limitation of the motor current

•

Control before commissioning

•

Measurement of the maximum surface temperature

during commissioning

•

Regular inspection and maintenance

Ignition hazard: mechanically generated sparks

Possible causes: improper assembly of leaks

•

Control before commissioning

•

Regular inspection and maintenance

Ignition hazard: electrostatic discharge

Possible causes: friction processes, potential differences

between components

•

Exclusive use of components with ATEX approval

•

Earth the gear unit housing

2.2 Personnel requirements

All work on the electrical equipment of the drive units must be

performed by qualified electricians. Installation, maintenance

and repairs of mechanical parts must be performed by fitters,

industrial mechanics or persons with comparable

qualifications.