TT-1303

7/02

3

Safety Precautions

Observe the following safety precautions while installing

the kit.

Accidental starting.

Can cause severe injury or death.

Disconnect the battery cables before

working

on

the

generator

set.

Remove the negative (--) lead first

when

disconnecting

the

battery.

Reconnect the negative (--) lead last

when reconnecting the battery.

WARNING

Disabling the generator set.

Accidental starting can

cause severe injury or death.

Before working on the

generator set or connected equipment, disable the generator

set as follows: (1) Move the generator set master switch to the

OFF position. (2) Disconnect the power to the battery charger.

(3) Remove the battery cables, negative (--) lead first.

Reconnect the negative (--) lead last when reconnecting the

battery. Follow these precautions to prevent starting of the

generator set by an automatic transfer switch, remote

start/stop switch, or engine start command from a remote

computer.

Installation Procedure

1.

Remove the generator set from service.

1.1

Place the generator set master switch in the OFF

position.

1.2

Disconnect the power to the battery charger, if

equipped.

1.3

Disconnect the generator set engine starting

battery(ies), negative (--) lead first.

2.

Mount

and

connect

the

controller

connection assembly.

2.1

GM17070-KP1

and

GM17070-KP1S

kits

(20--300 kW).

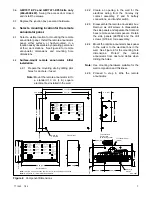

2.1.1

Remove the junction box rear panel and

the hardware.

2.1.2

Attach the controller connection assembly

(GM13984) to the junction box using six

screws (X-51-3), spacers (X-712-9), and

nuts (X-6210-4).

See Figure 2 for the

mounting locations.

2.1.3

Plug

the

wiring

connection

harness

(GM17033) into the controller connection

assembly’s P25 connector.

2.1.4

Proceed to step 2.4.

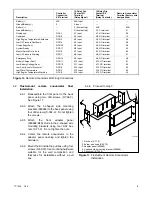

2.2

GM17070-KP2

and

GM17070-KP2S

kits

(350/400 kW).

2.2.1

Remove the junction box rear panel and

the hardware.

2.2.2

Remove the four screws attaching the

controller to the junction box.

See

Figure 3.

2.2.3

Mark the drill hole locations where the

terminal block bracket (347292) mounts to

the junction box top panel using the

dimensions given in Figure 3.

2.2.4

Move the controller away from the junction

box rear in order to provide enough

clearance to drill two 9 mm (0.344 in.)

diameter holes in the junction box top.

2.2.5

Remove the burrs from the drilled holes

and clean the metal chips from the junction

box.

GM17032-

1. Controller connection assembly (GM13984)

1

Figure 2

Controller Connection Assembly Mounting

Locations in Junction Box (20--300 kW)