TT-1303

7/02

5

2.6

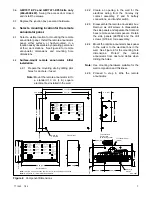

Plug the wiring harness connector into the

interconnection circuit board’s P23 connector.

Connect lead ES3 to TB1 terminal 3 and connect

lead ES4 to TB1 terminal 4. See Figure 5. If

access to the interconnection circuit board is

difficult, remove the two controller panel top

screws and center bottom screw and then loosen

the bottom screws on each side to swing the rear

controller panel down.

2.7

Swing the rear controller panel up and replace the

screws, if previously removed.

Replace the

controller cover and hardware.

Tighten all

controller screws.

3.

Mount the 14-relay dry contact box.

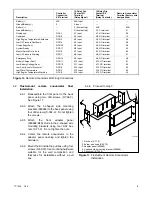

3.1

Determine a mounting location for the 14-relay dry

contact box (A-293983). See Figure 6. Consider

the supplied wiring harness length when choosing

a mounting location. If the most suitable location

requires a longer harness, fabricate a new

harness using the supplied harness as a guide.

Note:

The supplied wiring harness (293982)

allows a maximum distance of 1.5 m (5 ft.)

between the 14-relay dry contact box and

the controller connection terminal strip.

Choose one of the following mounting locations

for the 14-relay dry contact box, in order of

acceptability:

D

The junction box top; the size of the controller

and the size of the junction box limit the

mounting location.

D

The generator skid top; the clearance and

housing options limit the mounting location.

D

An area as near to the generator set controller

as practical.

3.2

Remove the four cover screws (X-6216-1) and lift

the box cover (256880) to access the internal

components.

3.3

Mount the 14-relay dry contact box in a location

selected

using

customer-supplied

mounting

hardware. The 14-relay dry contact box has four

7.5 mm (0.297 in.) diameter holes in the bottom

surface for mounting.

3.4

Wire the 14-relay dry contact box to the controller

connection terminal strip using the cable wiring

harness (293982). See Figure 7. Connect the

controller connection terminal strip terminals 2

(ground) and 42A (battery voltage) to the 14-relay

dry contact box terminal strip to provide an

electrical source to operate the K1--K14 relays.

A-365487-A/GM10193B

1. Interconnection circuit board (top view)

2. P23 connector

3. Interconnection circuit board mounted on the controller

rear panel

4. Connect lead ES3 to TB1 terminal 3 and connect lead ES4

to TB1 terminal 4

4

1

2

3

Figure 5

Attaching Wiring Connection Harness to

Controller Circuit Board

A-293983

P

FBA--1

42B

10 AMP

NO C

C

NO

C

NO

C

NO

C

NO

C

NO

C

NO

C

NO

C

NO

C

NO

C

NO

C

NO

C

NO

C

NO

K1

K2

K3

K4

K5

K6

K7

K8

K9

K10

K11

K12

K13

K14

INPUT

CONTACT RATINGS: 10A @120VAC RES. LOAD

.01A @28VDC MIN.

10A @28VDC MAX.

PCB ASSY A--320639

LOT NO.

42A 2

K1 K2 K3 K4 K5 K6 K7 K8 K9 K10 K11

K13 K14

K12

P

N

1. Cable wiring harness 293982 to the controller connection

terminal strip(s)

2. Cover screws

3. Annunciator wiring harness 256495 to the battery terminals

4. Mounting holes 7.5 mm (0.97 in.) diameter

1

2

3

4

Figure 6

14-Relay Dry Contact Box