Keep Gang Assemblies Tight

□ To ensure proper function and maximum durability, the axle nuts should be checked and

tightened daily during the first (7) days of operation when the disc is new or after replacing any of

the gang components.

□ Loose axles may bend or break or cause damage to other components of the gang assembly.

Maintaining tight gangs is necessary to ensure maximum bearing life.

□ A loose gang assembly is evident when some disc blades stop turning when discing or turn at a

different speed than other discs on the same assembly.

□ To tighten the axle without removing the gang assembly from the disc:

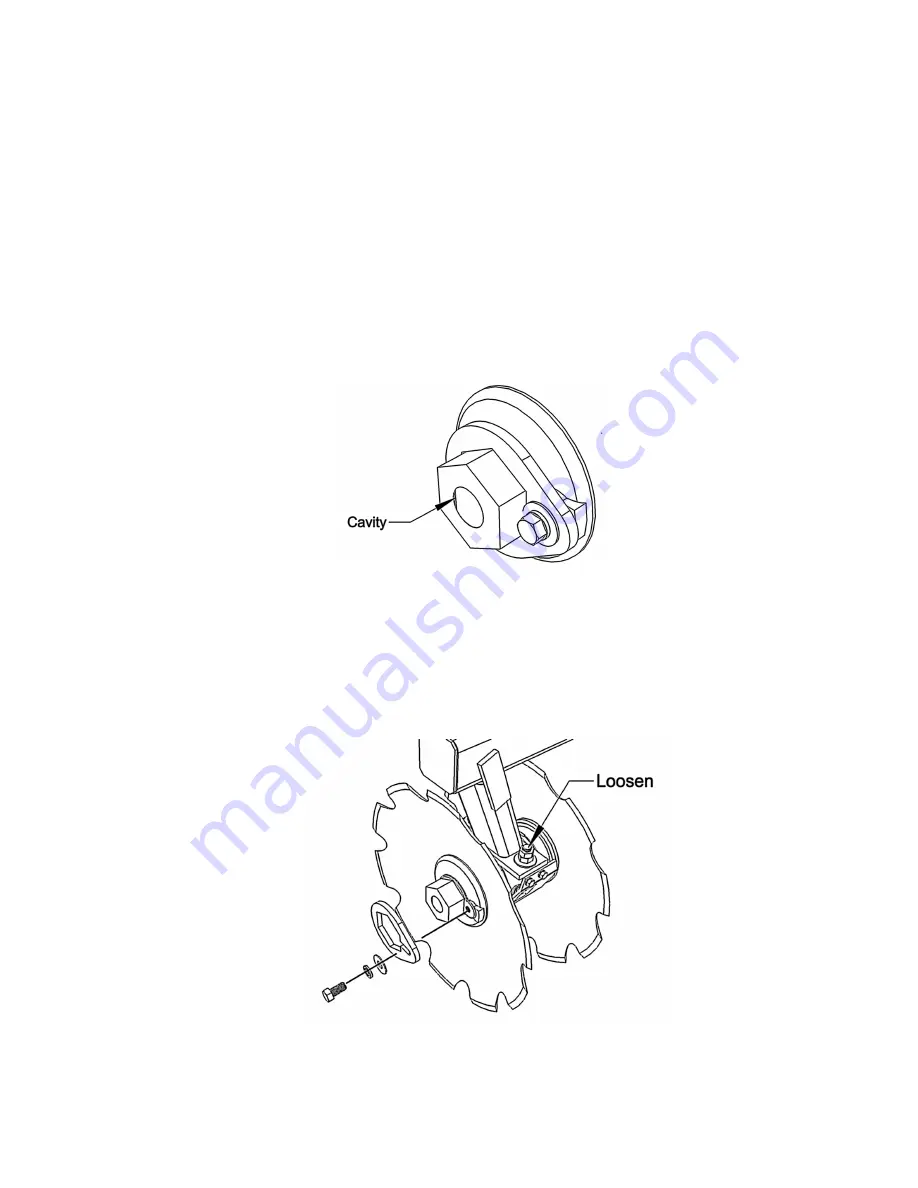

To minimize the possibility of thread damage, clean out the cavity between the inside of the nut

and the flat milled surface at the end of the axle. After using compressed air or a pressure

washer to remove as much material as possible, pour or spray a light oil or penetrating fluid into

the cavity.

Unbolt and remove the nut locks from the end washers on both ends of the axle.

Loosen but do not remove the bolts holding the bearings to the bearing standards.

Place one wrench on an axle nut to prevent the axle from turning.

Use the other wrench and an extension or a sledge hammer to tighten the axle nut on the opposite

end of the axle. Tighten the nut on 1-5/8” axle to 800-1000 ft/lbs and on a 2-1/8” axle to 1000-2000

ft/lbs.

Retighten the bearing bolts.

22