114

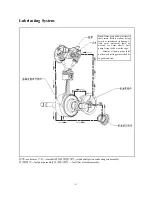

10. Lubricating System

Preparing documents -----------10.1

Failure diagnosis ----------------10.2

Fuel pump ------------------------10.3

10.1 Preparing documents

Work Instructions

Worm gears and worm wheels shall rotate flexibly without being seized or imbalanced tightening. A little axial

movement shall be allowed for worm wheels. Fuel pump O-ring shall not cut the edge.

Machine oil pump plugs shall not leak and sealing gaskets shall be in good condition.

After installation, remove bolt 3 during engine trial running, and lock it when machine oil runs out continuously.

Function of the lubricating system:

the lubricating system of the engine is to provide lubricating oil to the

frictional surface of each part, which transforms dry friction into liquid friction between lubricating oil particles

and also reduces abrasion of parts. It also cools components with high thermal load, absorbs shock from bearings

and other parts, reduces noise, increases sealing between piston ring and cylinder wall, and cleans and removes

particles in the surface.

10.2 Failure diagnosis

Decreasing fuel Burnt engine

Natural consumption of fuel No fuel or low fuel pressure

Fuel leakage Blocked fuel pipes

Abrasive or incorrectly installed piston ring No fuel used