F96VTN and G96VTN: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

18

Platform Furnace Support

Construct working platform at location where all required furnace

clearances are met. See

and

. For furnaces with 1-in. (25

mm) clearance requirement on side, set furnace on non-combustible

blocks, bricks or angle iron. For crawlspace installations, if the furnace

is not suspended from the floor joists, the ground underneath furnace

must be level and the furnace set on blocks or bricks.

Suspended Furnace Support

The furnace must be supported under the entire length of the furnace

with threaded rod and angle iron. See

. Secure angle iron to

bottom of furnace as shown.

Roll-Out Protection

Provide a minimum 12-in. x 22-in. (305 x 559 mm) piece of sheet metal

for flame roll-out protection in front of burner area for furnaces closer

than 12-in. (305 mm) above the combustible deck or suspended furnaces

closer than 12-in. (305 mm) to joists. The sheet metal MUST extend

underneath the furnace casing by 1-in. (25 mm) with the door removed.

The bottom closure panel on furnaces of widths 17-1/2-in. (445 mm) and

larger may be used for flame roll-out protection when bottom of furnace

is used for return air connection. See

roll-out shield.

A150580

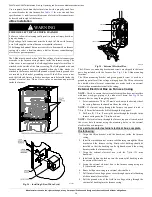

Fig. 26 – Working Platform for Attic Installation

NOTE:

Local codes may require a drain pan and condensate trap when

a condensing furnace is installed over a finished ceiling.

A150581

Fig. 27 – Suspended Furnace Installation

NOTE:

Local codes may require a drain pan and condensate trap when

a condensing furnace is installed over a finished ceiling.

Supply Air Connections

For a furnace not equipped with a cooling coil, the outlet duct shall be

provided with a removable access panel. This opening shall be

accessible when the furnace is installed and shall be of such a size that

the heat exchanger can be viewed for possible openings using light

assistance or a probe can be inserted for sampling the air stream. The

cover attachment shall prevent leaks.

Connect supply-air duct to flanges on furnace supply-air outlet. Bend

flange upward to 90° with wide duct pliers. See

. The supply-air

duct must be connected to ONLY the furnace supply-outlet-air duct

flanges or air conditioning coil casing (when used). DO NOT cut main

furnace casing side to attach supply air duct, humidifier, or other

accessories. All supply-side accessories MUST be connected to duct

external to furnace main casing.

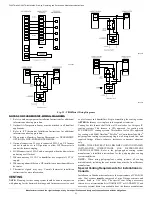

Return Air Connections

The return-air duct may be connected to bottom of the furnace. The side

of casing that faces downward may also be used for return air

connection. A combination of the bottom and downward facing side may

also be used. The upward facing side of the casing cannot be used as a

return air connection. See

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed in bottom

return-air opening. Remove and discard this panel when bottom return

air is used. To remove bottom closure panel see

.

Side Return Air Inlet

These furnaces are shipped with bottom closure panel installed in bottom

return-air opening. This panel MUST be in place when side return air

inlet(s) are used without a bottom return air inlet.

Not all horizontal furnaces are approved for side return air connections

. Where required by code, seal bottom closure to furnace with

tape, mastic or other durable sealing method.

2-IN.

(51 mm)

ROLLOUT PROTECTION REQUIRED

Install 12” x 22” (305x559 mm) sheet metal in front of burner compartment

area. The sheet metal MUST extend underneath the furnace casing by 1-in.

(25 mm) with the door removed. The bottom closure panel may be used for

flame roll-out protection when bottom of furnace is used for return air connection.

30 IN. (762 mm)

MIN. WORK AREA

COMBUSTION - AIR PIPE

(SEE VENTING SECTION)

2-IN.

(51 mm)

COMBUSTION-AIR PIPE

(SEE VENTING SECTION)

Install 12” x 22” (204 x 559 mm) sheet metal in front of and above the burner compartment area.

The sheet metal MUST extend above the furnace casing by 1-in. (25 mm with the door removed.

A 1-in. (25 mm) clearance minimum between top of furnace and combustible material is required.

The entire length of furnace must be supported when furnace is used in horizontal position to

ensure proper drainage.

NOTE: FURNACE SHOWN IS A DIRECT-VENT APPLICATION. REFER TO THE VENTING SECTION FOR

ALLOWABLE VENT CONFIGURATIONS.

ROLLOUT PROTECTION REQUIRED