F96VTN and G96VTN: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

50

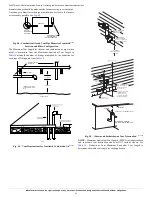

Determine an appropriate location for termination kit using the

guidelines provided in section “Locating The Vent Termination” in this

instruction.

1. Cut two holes, one for each pipe, of appropriate size for pipe size

being used.

2. Loosely install elbow in bracket (if used) and place assembly on

combustion-air pipe.

3. Install bracket as shown in

and

NOTE:

For applications using vent pipe option indicated by dashed

lines in

_

from position.

4. Disassemble loose pipe fittings. Clean and cement using same

procedures as used for system piping.

DO NOT CEMENT

POLYPROPYLENE FITTINGS.

(Direct Vent / 2-Pipe System ONLY)

When two or more furnaces are vented near each other, two vent

terminations may be installed as shown in

, but next vent

termination, or pair of vent terminations, must be at least 36 in. (914

mm) away from the first two terminations. It is important that vent

terminations be made as shown in

to avoid recirculation of vent

gases.

Inducer Outlet Restrictor

To improve efficiency and operation of 40K, 60K or 100K BTUH input

models on very short vent systems, an inducer outlet restrictor is

required to be installed on the outlet of the inducer assembly. The outlet

restrictor is shown in the footnote of

Vent Length. The outlet restrictor for 40K models is shipped in the loose

for usage, part numbers and sourcing of 60K and

100K inducer outlet restrictors.

To determine if the outlet restrictor is required, see

.

Failure to

use an outlet restrictor on the 40K model when required may result

in flame disturbance or flame sense lockout.

To install the outlet restrictor:

1. Remove the vent elbow from the inducer outlet.

2. Align the lock tabs on the outlet restrictor with the slots on inside

outlet of the inducer assembly.

3. Snap the outlet restrictor in place.

4. Re-install the vent elbow.

5. Torque vent elbow clamp 15-lb-in.

Venting System Length Calculations

The Total Equivalent Vent Length (TEVL) for

EACH

combustion air or vent pipe equals the length of the venting system, plus the equivalent length of

elbows used in the venting system from

.

Standard vent terminations or factory accessory concentric vent terminations count for zero deduction.

See vent system manufacturer’s data for equivalent lengths of flexible vent pipe or other termination systems.

DO NOT ASSUME

that one foot of

flexible vent pipe equals one foot of straight PVC/ABS DWV vent pipe.

Compare the Total Equivalent Vent Length to the Maximum Equivalent Vent Lengths in

Example 1

A direct-vent 60,000 BTUH furnace installed at 2100 ft. (640M). Venting system includes

FOR EACH PIPE:

70 feet (22 M) of

vent pipe, 65 feet (20 M) of combustion air inlet pipe, (3) 90º long-radius elbows, (2) 45º long-radius elbows, and a factory accessory

concentric vent kit.

Can this application use 2” (50 mm ND) PVC/ABS DWV vent piping?

Measure the required linear length of air inlet and vent pipe; insert the longest of

the two here

=

70 ft.

(22 M)

Use length of the longer of the vent

or air inlet piping system

Add equiv length of (3) 90º long-radius elbows

(use the highest number of elbows for either the vent or

inlet pipe)

3

x

3 ft.

(0.9 M)

=

9 ft.

(2.7 M)

Add equiv length of (2) 45º long-radius elbows

(use the highest number of elbows for either the vent or

inlet pipe)

2

x

1.5 ft.

(0.5 M)

=

3 ft.

(0.9 M)

Add equiv length of factory concentric vent term

0 ft.

Add correction for flexible vent pipe, if any

0 ft.

From Vent Manufacturer’s

instructions; zero for PVC/ABS DWV

Total Equivalent Vent Length (TEVL)

82 ft.

(25 M)

Add all of the above lines

Maximum Equivalent Vent Length (MEVL)

95 ft.

(29 M)

Is TEVL less than MEVL?

YES

Therefore, 2” pipe MAY be used