-

4

Danger

Risk of injury, risk of damage!

Observe the weight of the appliance when

you load it!

Remove the cardboard.

Remove the wooden blocks that secure

the wheels and raise the device from

the pallette by hand.

Release parking brake.

Loosen the screws.

Align the pushing handle.

Tighten the screws.

Notice

–

The appliance may only be tilted back-

wards if the fuel tank is empty.

–

Close the fuel tap, remove the waste

container and move the pushing handle

to the front prior to tilting the appliance.

Do not rest the appliance on the push-

ing handle.

Clip side brush on to driver and screw

on.

Danger

Risk of injury! Switch off the appliance prior

to removing the waste container.

Notice

Only operate while the appliance hood is

closed. The appliance is equipped with a

hood contact switch to protect the operator.

The motor starts up only when the appli-

ance hood is closed.

Park the sweeper on an even surface.

Switch off engine.

Lock parking brake.

Danger

Risk of explosion!

–

Only use the fuels specified in the Op-

erations Manual.

–

Do not refuel the machine in enclosed

spaces.

–

Smoking and naked flames are strictly

prohibited.

–

Ensure that no fuel reaches the hot

open surfaces.

Switch off engine.

Open fuel filler cap.

Use "regular unleaded petrol".

Fill tank to max. 1 cm below the lower

edge of the filler nozzle.

Wipe off any spilt fuel and close fuel fill-

er cap.

Note

The machine can be operated for a maxi-

mum of 2.0 hours on a full tank.

Carry out the daily maintenance tasks (see

section "Maintenance and Care").

Check engine oil level.

Check and ensure proper fitting of the

spark plug.

Check side brush.

Check roller brush.

Shake off dust filter.

Empty waste container.

Danger

Ensure that there is adequate ventilation or

provision for diverting the exhaust gas

while operating the appliance in closed

rooms (risk of poisoning).

Open the device hood.

Open the fuel supply.

Turn the rotating knob parallel to the

hose of the fuel tap.

Close cover.

Release parking brake.

Slide the multifunctional lever into the

center position "Operation speed"; if the

weather is cold or wet, move it to the

"Choke“ position.

Pull the starter rope slowly until a resist-

ance can be felt.

Pull starter rope swiftly.

Once the motor runs, release the starter

rope. Move the multifunctional lever

from the "Choke" into the "Operating

speed" position.

Note

The appliance works best while in the

operating position.

Note

The sweep roller and the side-brushes start

rotating.

Pull the lever for forward drive.

Note

The drive speed for forward drive can be

adjusted steplessly depending on the posi-

tion of the lever.

Release the lever for forward drive. De-

vice comes to a halt.

Driving over fixed obstacles which are 30

mm high or less:

Raise bulk waste flap.

Drive forwards slowly and carefully.

Driving over fixed obstacles which are

more than 30 mm high:

Only drive over these obstacles using a

suitable ramp.

Danger

Risk of injury! If the bulk waste flap is open,

stones or gravel may be flung forwards by

the roller brush. Make sure that this does

not endanger persons, animals or objects.

몇

Warning

Do not sweep up packing strips, wire or

similar objects as this may damage the

sweeping mechanism.

Note

To achieve an optimum cleaning result, the

driving speed should be adjusted to take

specific situations into account.

Note

To sweep up larger items up to a height of

50 mm, e.g. cigarette packs, the bulk waste

flap must be raised briefly.

Raising bulk waste flap:

Pull the lever for raising the bulk waste

flap.

Lowering the bulk waste flap:

Release the lever for raising the bulk

waste flap.

Note

An optimum cleaning result can only be

achieved if the bulk waste flap has been

lowered completely.

Move the lever to lower the side brush

to the front. The side brush will be low-

ered.

Note

Empty the waste container at regular inter-

vals during the sweeping operation.

Note

During operation, the dust filter should be

shaken off and cleaned at regular intervals.

Close wet/dry flap

Open wet/dry flap.

Note

This protects the filter from moisture.

Before Startup

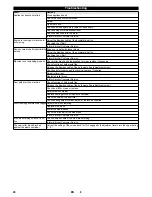

Unloading tips

Net weight (transport weight) 84 kg

Unloading

Installing the pushing handle

Install side brush

Start up

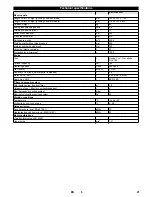

General notes

Refuelling

Inspection and maintenance work

Operation

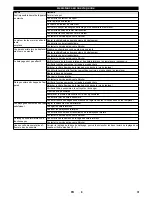

Starting the machine

Open fuel cock

Start the engine

Drive the machine

Drive forward

Dry run

Driving over obstacles

Sweeping mode

Sweeping with bulk waste flap raised

Sweeping with side brushes

Sweeping dry floors

Sweeping damp or wet floors

16

EN

Summary of Contents for KM 75/40 W G

Page 22: ...283...