-

2

Your sales outlet should be informed about

any transit damage noted when unpacking

the product.

–

Warning and information plates on the

machine provide important directions

for safe operation.

–

In addition to the information contained

in the operating instructions, all statuto-

ry safety and accident prevention regu-

lations must be observed.

Danger

Risk of injury!

Danger of tipping if gradient is too high.

–

The gradient in the direction of travel

should not exceed 15%.

Danger of tipping on unstable ground.

–

Only use the machine on sound surfaces.

Danger of tipping with excessive sideways

tilt.

–

The gradient perpendicular to the direc-

tion of travel should not exceed 15%.

–

It is important to follow all safety instruc-

tions, rules and regulations applicable

for driving motor vehicles.

–

The operator must use the appliance

properly. He must consider the local

conditions and must pay attention to

third parties, in particular children, when

working with the appliance.

–

The appliance may only be used by per-

sons who have been instructed in han-

dling the appliance or have proven

qualification and expertise in operating

the appliance or have been explicitly

assigned the task of handling the appli-

ance.

–

The appliance must not be operated by

children, young persons or persons

who have not been instructed accord-

ingly.

Never leave the machine unattended

so long as the engine is running. The

operator may leave the appliance only

when the engine has come to a stand-

still, the appliance has been protected

against accidental movement, and the

emergency brake has been locked.

Danger

Risk of injury!

–

Do not close the exhaust.

–

Do not bend over the exhaust or touch

it (risk of burns).

–

Do not touch the drive motor (risk of

burns).

–

Ensure that there is adequate ventila-

tion or provision for diverting the ex-

haust gas while operating the appliance

in closed rooms (risk of poisoning).

–

Exhaust gases are poisonous and haz-

ardous to health, do not inhale them.

–

The engine requires approx. 3-4 sec-

onds to come to a standstill once it has

been switched off. During this time, stay

well clear of the working area.

–

The appliance may only be tilted back-

wards if the fuel tank is empty.

The engine is to be brought to a standstill

and the appliance is to be fastened proper-

ly during transportation.

Refer to Chapter "Transport".

Danger

If the appliance hood is opened while the

motor is running, the motor has to switch

off. If the motor does not shut off, there is a

defect on the hood contact switch. Inform

customer service.

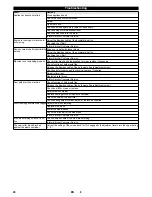

Symbols on the machine

Risk of burns on account of

hot surfaces!

Please do not sweep away

any burning substances

such as cigarettes, match

sticks or similar objects.

Risk of being squeezed or

hurt at the belts, side-brush-

es, containers, pushing han-

dle.

Risk of injury on account of

rotating roller brush. Open

the appliance hood only

when the engine has come

to a halt.

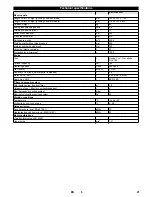

Safety instructions

General notes

Safety information concerning the

driving operation

Safety information concerning the

combustion engine

Safety information concerning the

transport of the appliance

Open/ close device hood

14

EN

Summary of Contents for KM 75/40 W G

Page 22: ...283...