CH-X470RF

1-13

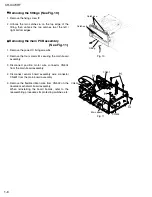

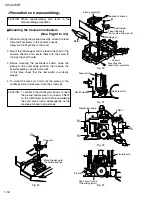

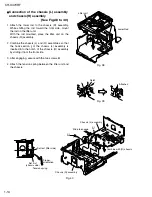

Insert the shafts f of the traverse mechanism

assembly into the slide grooves g on the lifter unit.

Shift the hook of the lifter unit to the edge, and shift

the sliding lever inside the side bracket unit to the

edge as well.

With each hole and lever shifted to the edge, mount

the lifter unit and side bracket unit from the side.

(Check each attached section, and check that the

two shafts h of the lifter unit are correctly inserted

into the holes i of the side bracket unit. After

mounting, check that the levers move together. )

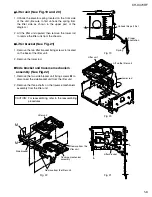

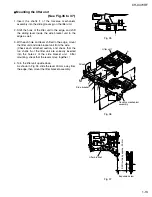

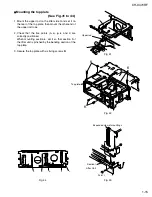

Turn the lifter unit upside down.

As shown in Fig. 35, slide the lever 30 mm away from

the edge, then mount the lifter bracket assembly.

1.

2.

3.

4.

Mounting the lifter unit

(See Fig.35 to 37)

f

f

f

h

Attach

Shift inside b

y

appro

x.

30 mm

Expanded view

i

g

g

g

Fig. 35

Fig. 36

Fig. 37

Lifter unit

M

Side bracket

Traverse mechanism

assembly

Lifter bracket