-

33

-

⇔

⇩

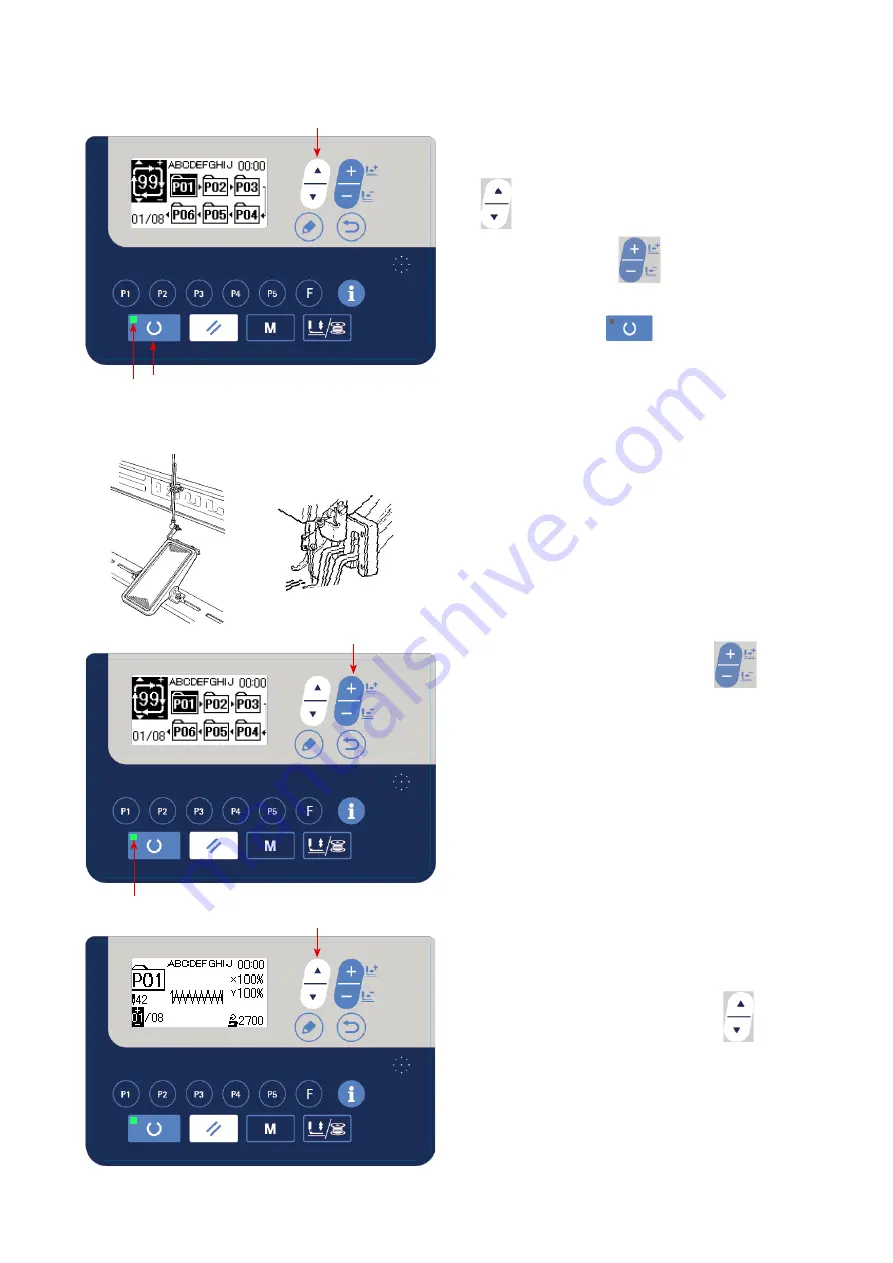

(3) Sewing operation

1) Turn the power ON.

2) Select the cycle pattern using ITEM SELECT key

❻

. Select the cycle pattern number with

DATA CHANGE key

❼

.

3) Press READY key

❷

to light up SET

READY LED

. Then, the work clamp goes up

after travelling.

4) If the pattern shape is correct, start sewing.

5) The step of pattern numbers combined on a

sewing-by-sewing basis advances until one cycle

is completed. After the completion of the cycle,

the sewing machine returns to the first step of the

cycle to permit sewing in repetition.

* When you want to return to the previous pattern

after the completion of sewing or to skip the next

pattern, press DATA CHANGE key

❼

while SET READY LED

lights up.

The pattern display changes and the work clamp

travels to the sewing starting point.

* Be aware that the contents of P1 to P50 used

for C1 to C99 will be changed if you change the

contents of P1 to P50 after the registration of C1

to C99.

* Check the pattern shape on a pattern-by-pattern

"I.5-4. Checking the contour of

.)

* When you press ITEM SELECT key

❻

on

the sewing screen, the details of the pattern to be

sewn can be displayed.

❻

❷

❼

❻

➡