−

52

−

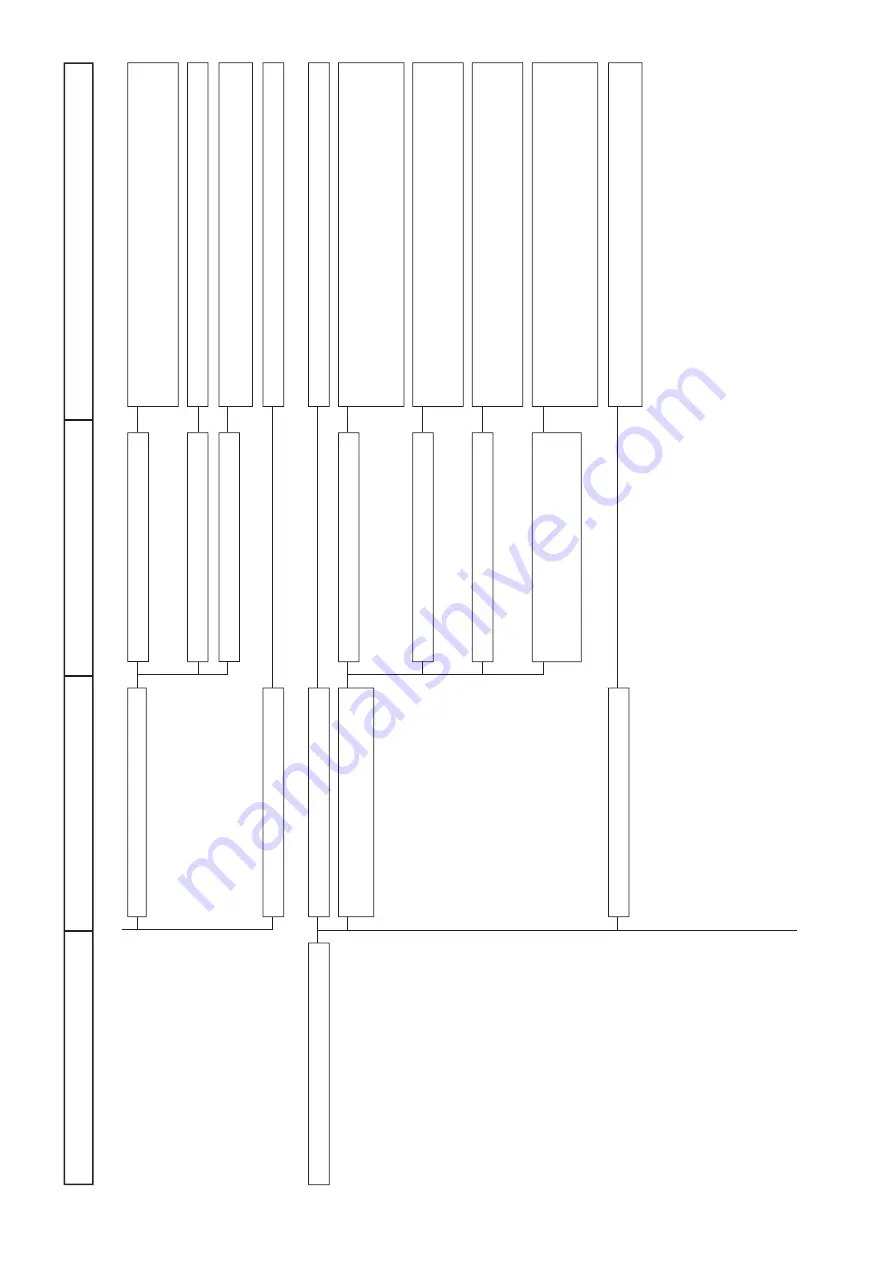

Troubles

Cause (1)

Cause (2)

Checking orders and corrective measures

From the previous page

Balloon stitches

Presser foot is defective.

Number of revolution is high.

Thread tension is low.

Thread take-up spring is improperly

adjusted.

Stroke of thread take-up is large.

Presser foot pressure is too high.

Finish of presser foot sole is bad.

Material is hard to be slipped.

Stroke of thread take-up spring is small.

Tension is low.

Shape of thread take-up spring is improper.

Strength of thread take-up spring is weak.

Follow-up capability at high speed is

defective.

Minimize the pressure. For some materials, it is effective to use

the micro-lifter screw and sew in the state that the presser foot is

slightly raised.

Polish with buff or the like to improve the slide.

Use the teflon presser foot, or specially processed (teflon, etc.)

presser foot.

Decrease the number of revolution.

Increase the tension of thread tension No. 2.

Balloon stitch or thread breakage is apt to occur if the stroke of

thread take-up spring is small since the released thread is not

pulled up enough. Adjust the stroke of thread take-up spring to a

rather large value.

If the tensin is too low, when the machine runs at high speed, the

spring cannot follow up and pulling-up of thread is deteriorated.

As a result, balloon stitch or thread breakage is apt to occur.

If the top end of thread take-up spring is opened, thread may be

caught with it when thread is slackened. Close the top end with

fingers when it is excessively opened.

The weak thread take-up spring of A type does not show the

effect enough for the thread of # 60 or more since the tension at

the end of motion does not become large. In this case, replace it

with the standard thread take-up spring (or thread tension).

Move the arm thread guide to the right to decrease the supplying

amount of thread by the thread take-up.

To the next page

▼